Windows

Intro

As with many aspects of choosing building materials it is necessary to balance the spec against the cost. Good building design also means good value for money or else hardly anyone will build to that house design. When choosing windows it's good to have a starting point spec in mind, but you will likely need to compromise in order to get good value.

Geographical location

If you live in a cold climate then you will need a different spec than if you live in Florida or some other southern place. In pretty much all places you will want windows that have good insulation values so that they either keep the heat in to reduce heating costs, or keep the sun's heat out to reduce air conditioning costs. In a southern climate however you want a low Solar Heat Gain Coefficient (SHGC) to further help keep the sun out, whereas in a northern cold climate you want a high SHGC to let the warming rays of the sun into your house as much as possible.

In my case I'm in a cold climate (Seattle, USA) so for most days of the year it is necessary to heat the house and there are only a couple of dozen days where an air conditioner would be useful. In this web page I will primarily concentrate on the requirements for northern cold climates.

Window frames (or not)

If you are using a non-opening fixed window then there is no fundamental reason why you need to buy your windows with any kind of frame. If you design a suitable mounting mechanism in your rough wall openings then you can directly mount a raw Insulated Glass Unit (IGU). An IGU is two pieces of glass bonded together with a gap between them. The edges of an IGU are raw glass. If you don't provide a nice cushioned mounting mechanism in your wall opening then of course you might crack the glass and for this reason most North American manufacturers are reluctant to supply raw IGUs, and if they do then you probably won't get a warrantee. In the UK it is fairly common to buy IGUs, but given that I'm building in America I reluctantly decided to go with the flow and use windows with frames.

Types of window frame

There is a certain snobbery associated with the choice of window frames. Most people are conditioned to think that wood or wood clad in aluminum is what you want in upmarket windows. The problem with wood is that it rots and you have to keep painting it to try to slow down the rotting process. The problem with aluminum clad windows (at least from some manufacturers) is that water can find its way behind the aluminum and get trapped and rot the wood. Fiberglass is a good material to make frames out of, and you can paint it a color of your choice, but fiberglass frames tend to be expensive. Vinyl is also a great material for window frames and it's a lot cheaper than fiberglass.

Vinyl lasts pretty much for ever and it never needs painting. Because it's low cost, vinyl windows get regarded as the bottom end of the market and some people turn their noses up at it. Don't get fooled by this snobbery. Vinyl windows are the best engineering solution for implementing window frames. They are cost effective and yet degrade less with time than other solutions, and need no maintenance to keep performing well. I chose vinyl window frames.

You cannot paint vinyl windows (at least not easily or well) and you typically only get to choose between white and brown. Each manufacturer offers their own shade of brown so matching different brands of vinyl windows in a house is a problem. The bottom line is that you are best off choosing white window frames. Personally I prefer the look of white window frames so I would have chosen white anyway.

Types of opening window

Even in a house that is designed to be sealed, with the fresh air supplied by a mechanical ventilator (ERV or HRV), it is necessary to have some opening windows in order to for example provide emergency escape from bedrooms. Sometimes it is just nice to have a window you can lean out of to water your flower garden. You can choose horizontal slider windows, or double or single hung windows, or casement windows. My preferred choice is to use casement windows. The main reason is that they provide a better air seal when closed. Air leaks are the biggest contributor to heat loss and so this will have a direct beneficial effect on your heating bill. The down side with casement windows is that they cost a bit more and the maximum size is about 3 foot wide by 4 foot high. Personally I love the way that casements open. You just turn a handle. You can even attach a motor to the handle shaft and automate them. If you need a bigger window then you make a composite window that consists of a casement window with one or more fixed picture windows attached.

My ideal spec

Without going overboard, here's the starting point spec that I decided would be my ideal affordable window. I was not trying to go as hard core as the PassivHaus folks because I knew that importing windows from Germany would be an expensive proposition. I was trying to set a spec that I thought American window manufacturers ought to be able to achieve in mainstream double glazed argon windows.

U-factor / R-value

Whole window U less than 0.33 (R higher than 3)

Center of glass U less than 0.29 (R higher than 3.45)

U-factor is what most manufacturers specify. If you want the more useful R-value then you just take the inverse of the U-factor (R = 1/U). Both U and R describe exactly the same thing about a window, ie how well it insulates and therefore prevents heat travelling through the window. You want the U to be as low as possible and that corresponds to the R being as high as possible.

Some manufacturers specify the value in just the center of the glass area (because it makes the value look more favorable to the manufacturer) and some specify the value for the whole window including the frame. The "whole window" approach is much better because it allows for any bad thermal bridging that occurs if a poor spacer is used between the sheets of glass. An aluminum spacer is bad because aluminum conducts heat whereas you are trying to achieve good insulation between the two sides of the window.

SHGC (Solar heat gain coefficient)

Whole window higher than 0.4

Center of glass higher than 0.6

SHGC is a measure of how much the heat from the sun's rays can get into your house to heat up the thermal mass that is inside the thermal envelope of your house. In a cold climate you typically want the sun's rays to get into your house as much as possible to reduce your heating bill. The down side with a high SHGC is that if you are in a hot climate it will increase your air conditioning electricity bill. In a cold climate it might even make the difference between not having an air conditioning system and needing to install one. The effect of the solar heating can be reduced in the summer relative to the winter buy providing shading overhangs on the outside of the building, because in the winter the sun is lower in the sky and so can shine under the overhang awnings.

The bottom line is that in my cold climate I want a fairly high SHGC, but I don't want to overdo it or else I would have the expense of needing to install air conditioning for the couple of weeks when we get sun. I want a fairly high SHGC but I am prepared to be flexible on this spec figure in order to get affordable windows.

VT (Visible Transmittance)

Above 0.45

If only you did not need to be able to see through windows then you could give them a really great insulation value. I could make "windows" out of polystyrene sheet and they would have a fantastic U value, but nobody would buy them because you wouldn't be able to see through them. Some triple glazed windows use a sheet of plastic in the middle and get a great U value, but it's at the expense of the VT value.

Gas in the gap

Argon

Having gas between the sheets of glass is really just an implementation detail necessary to achieve the insulation spec. A vacuum provides some insulation, but using the right gas does better. The two gas choices are Argon or Krypton. Argon is the most cost effective way, because Krypton is hugely expensive. With Argon you need a half inch gap between the sheets of glass, whereas Krypton needs less of a separation. The only real justification for using Krypton is if you have an architectural planning restriction that limits the overall thickness of glass you are allowed to use. With Argon the optimum gap between the sheets of glass is 0.5".

Glass Coating

LowE

Again this is really just an implementation detail necessary to achieve the insulation value. The biggest criteria is choosing a window where the LowE coatings are on the inside so that they don't get rubbed off. If the manufacturer offers two product variants , "Advanced LowE" and also "LowE", then choose the "Advanced LowE" as it will provide better insulation.

Spacer

"Warm spacer"

"Insulating spacer"

This refers to the thing that goes all the way round the outside of the glass assembly to hold the two bits of glass half an inch apart and to seal it so that the gas is held in. Many manufacturers used to use a spacer made of aluminum, but this is a bad choice because aluminum conducts heat well and we don't want heat to be conducted from inside the house to the outside. The spacer is the biggest reason why the "whole window" spec for a window is worse than the "center of glass" spec. A "warn spacer" refers to an implementation that aims to reduce the amount of heat transfer.

Safety Glass

Tempered

This refers to how hard it is to break the window and what happens if it does break. Tempering glass involves heating it in a furnace and then quickly blowing cold air on it. It makes it much tougher such that it is about 4 or 5 times harder to break. If it does break then it breaks up into little cubes of glass that are much less likely to cut anyone. The downside with specifying tempered glass is that it increases the window cost by about 50%. Despite the large cost increase I decided to use tempered glass because of the peace of mind it gives. I don't want to worry about small children accidentally running into a window and glass knives falling on them. I regard it as particularly important with a large window for it to be tempered. Building code only requires tempered glass (ie safety glass) to be used for windows that are within 2.5 feet of door openings.

Self cleaning

Nice to have

This is a clever coating on the outside surface of the glass that helps breakdown dirt such that the rain can wash the dirt away. I would love to have this but it is old really available from Pilkington Glass in the UK. As I'm building in North America I had to do without this.

Anti-fade for furniture

No

It is possible to put a coating on the glass that reduces the amount of UV light that can pass through the window to fade your furniture. The down side is that the coating also tends to reduce the SHGC which is not what you want in a cold climate. Personally I don't have much fancy furniture so I don't really care. I don't want the coating because I want to keep the SHGC fairly high. I dislike in general films that are applied to the outside of the glass because it can scratch and then look really bad.

Tinting or coloring

No

Personally I don't want anything to spoil the view out of my windows. I also don't have any neighbors near me so privacy is not an issue.

Grid between the glass panes

No

Some people think that a cross hatch grid between the two panes of glass looks nice, but personally I don't want anything getting in the way of the view out of the window.

Air leakage

Very low

Achieving a very low air leakage for your overall house enclosure is a really big deal if you want good energy efficiency. Air currents are the biggest transfer mechanism for heat escaping from your house. An openable window that does not form a good seal when shut will make it impossible to achieve your overall house air leakage spec. Casement windows typically shut much tighter than other window types (eg sliding windows) and so I use casement windows whenever I need an openable window.

Bug screen

Yes

I hate bugs, particularly mosquitos, so I regard having a bug screen as a big benefit on opening windows and any doors that will be left open.

Maximum size

Fixed picture windows: 8' high by 5' wide

Casement windows: 4' high by 3' wide

Establishing the maximum size is an iterative process between what you would ideally like for your house design and what your chosen window manufacturer is able to do. You will likely need to do some adjustment to your house drawings after picking a particular window supplier.

I decided in my house design to where possible go for whole number of feet minus 1/2". Even though a manufacturer could do 96x60 it is better to get 95-1/2 by 59-1/2 as this is more standard and so will make it easier to find replacement windows if needed.

Quantity

(Detailed list of windows with quantities for complete house)

It is necessary to have a detailed list or the window manufacturer will not be able to do a proper quote and will probably not take you seriously. Go through your house drawings in detail and allocate each window size/type a different identifier. Eg you might decide the different picture window sizes will be called P1, P2, etc and the casement windows will be called C1, C2, etc. Count up the numbers for each size/type, eg 10 off of P1, 5 off of P2, etc. Also provide a key that explains what each window is. It's best to spec the outside frame dimension (which is typically 0.5" smaller than the rough opening in the wall. Eg P1 is 59.5" x 95.5".

For casement windows you may well need picture windows next to them to achieve the desired size. Some manufacturers can do this by welding windows together but this may be costly. Alternatively you might decide to use windows with the standard nail fin and use your own joining mechanism between the fins (at the expense of a wider gap between glass areas).

Here's the list for my house...

Ident Type

Window frame

P1 Fixed Picture Tempered

W:59.5", H:95.5"

P2 Fixed Picture Tempered

W:59.5", H:47.5"

P3 Fixed Picture Tempered

W:71.5", H:29.5"

P4 Fixed Picture Tempered

W:59.5", H:29.5"

P5 Fixed Picture Tempered

W:71.5", H:47.5"

P6 Fixed Picture Tempered

W:47.5", H:71.5"

P7 Fixed Picture Tempered

W:47.5", H:35.5"

P8 Fixed Picture Tempered

W:35.5", H:47.5"

P9 Fixed Picture Tempered

W:35.5", H:95.5"

P10 Fixed Picture Tempered

W:59.5", H:44.5"

P11 Fixed Picture Tempered

W:71.5", H:44.5"

P12 Fixed Picture Tempered

W:20.5", H:47.5"

P13 Fixed Picture Tempered

W:32.5", H:47.5"

R1 Round Fixed Picture Tempered

W:59.5", H:59.5"

T1 Triangle Fixed Picture Tempered W:119.5", H:41.5"

C1 Casement, hinge right, Tempered, Bug screen

W:35.5", H:47.5

C2 Casement, hinge left, Tempered,

Bug screen W:35.5",

H:47.5

D1 Glass sliding Door, right opens, bug screen,

Advanced LowE with Argon

W:59.5, H:79.5"

D1 Glass sliding Door, left opens, bug screen, Advanced

LowE with Argon, external keylock W:59.5, H:79.5"

D2 Glass Patio Door, right opens, bug screen, Advanced

LowE with Argon

W:71.5, H:79.5"

D2 Glass Patio Door, left opens, bug screen, Advanced

LowE with Argon W:71.5,

H:79.5"

D3 Glass Swing Door, bug screens,

Advanced LowE with Argon

W:71.5, H:79.5"

***** Quantities *****

P1 16

P2 4

P3 2

P4 5

P5 14

P6 4

P7 1

P8 5

P9 1

P10 1

P11 1

P12 1

P13 5

R1 2

T1 4

C1 7

C2 6

D1R 5

D1L 2

D2R 1

D2L 2

D3 1

Selecting a supplier

The process

Once you have a spec (such as the one given above) then you need to give it to the various window suppliers in your area. Some suppliers you can deal with directly and some sell through home centers such as Lowes or Home Depot. The various suppliers will be able to quote you a price and let you know their spec relative to your ideal spec. It is then up to you to balance price against spec. You might decide to pay less for windows with a slightly inferior insulation value and just accept that your heating bill will be a bit higher.

Negotiate

Don't go into the window manufacturer selection process with a fixed idea about which company you are going to use. Let the combination of spec and price determine the window manufacturer you choose.

Often you will be told that no negotiation on price is possible and that you just need to accept whatever price the estimation computer program comes up with. If a company does not want to play ball then they are likely to loose relative to another company that is prepared to lower their price to win your business.

Sometimes the thing that makes the biggest difference is how the manufacturer decides to class you. If you are classed as a "homeowner" then the price is likely to be higher than if you are classed as a "residential building company", and that price may be higher than if you were classed as a "commercial building company". You need to walk the walk and talk the talk to be classed as favorably as possible.

And the winner is

In my case after talking to lots of raw glass manufacturers and window manufacturers, my choice was Pella using their Encompass range. The SHGC was not as high as I wanted, but the price was right so I accepted the slightly increased heating cost. The spec is as detailed bellow.

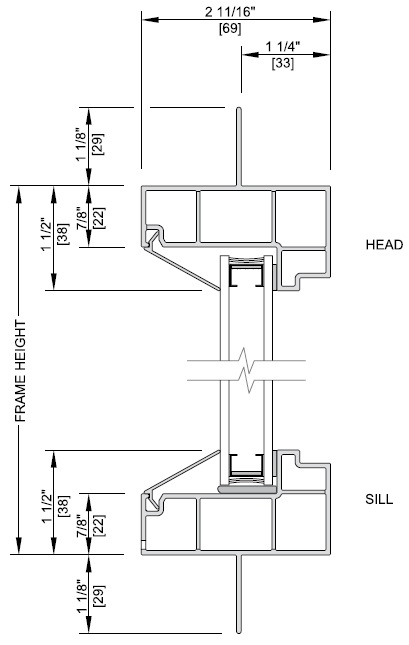

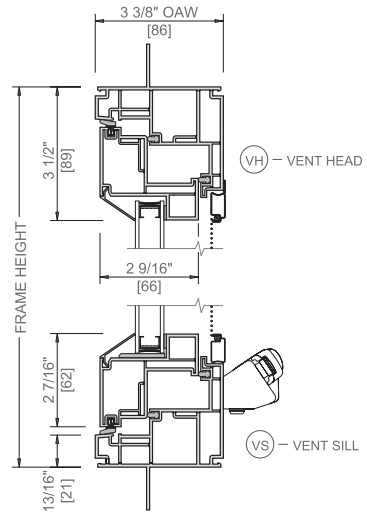

Pella Encompass

Vinyl frames with Tempered Low E Advanced glass and Argon Gas.

Extruded, rigid PVC (Poly Vinyl Chloride) frame with heat-fused mitered corners to give a fully welded corner assembly. Pella Encompass 10 series. Has a nail flange for mounting in the wall. Float glass complying with ASTM C1036. Glass manufactured by Cardinal.

Frame surround is 1-1/2" (subtract 3" from frame size to

get visible glass size).

Nail flange is 1-1/8" (over and above frame size).

Manufactured in Portland Oregon.

Picture windows up to 8' high by 5' wide.

Casement windows of a smaller size. (4' high by 3' wide ok).

Spec (whole window)

Whole window: U: 0.28 R: 3.57

SHGC: 0.32

VT: 0.61

Drawings

Backer Rod

The quarter inch gap round the window (or door) on the inside should be filled with backer rod with some white caulking over that. You may need 3/8" backer rod to provide a nice tight fit.

http://smile.amazon.com/gp/product/B000DZHF4Q/ref=pe_852090_154090750_em_1p_5_ti

$5.01 for 100 feet.

Resources

National Fenestration Rating Council

The National Fenestration Rating Council (NFRC) rates windows on three criteria: U-factor, SHGC, and visual transmittance (VT). NFRC ratings for U-factor and SHGC are whole-window ratings, not glass-only ratings.

Energy Star

In northern climates, an Energy Star-rated window must have a maximum U-factor of 0.35, the equivalent of an R-2.8 insulated wall (but you should aim for better than this figure).

GreenBuildingAdvisor

http://www.greenbuildingadvisor.com/green-basics/windows-glass-ratings-and-installation-0

http://www.greenbuildingadvisor.com/blogs/dept/musings/passivhaus-windows

http://www.greenbuildingadvisor.com/blogs/dept/musings/windows-perform-better-walls

http://www.greenbuildingadvisor.com/blogs/dept/musings/choosing-triple-glazed-windowsv

Other

http://www.efficientwindows.org/

Tax credits

http://www.energystar.gov/index.cfm?c=tax_credits.tx_index