Home Site Map - Techniques - Interior Infrastructure -

Ventilation

![]() How to select the best Heat Recovery Ventilation system for your

house.

How to select the best Heat Recovery Ventilation system for your

house.

Basic principles

A sealed house needs specific ventilation designed in

The house will be (and for energy efficiency needs to be) tightly sealed, ie highly air tight. This gives you complete control over the air coming into your house (which is a very good thing), but it's important to make sure there is enough air coming into the house so you don't suffocate or feel groggy. You need either an ERV (Energy Recovery Ventilator) or an HRV (Heat Recovery Ventilator).

Even if you cannot afford the $600 - $2000 that an ERV/HRV will cost, you should at least implement the ducting for installing one. Use a simple inline fan where the ERV/HRV will go until you have saved up the necessary money.

At minimum (according to ASHRE) the ventilation system needs to be big enough to change 0.3 of the house air volume every hour. I think that for healthy living it is better to change about half (0.5) of the house air every hour.

The house should be designed to be air tight and door blower tested to be better than 1 Air Change per Hour at a pressure of 50 Pascals (ACH50), ideally better than 0.5 ACH @ 50 Pascals.

A garage space that is used for vehicles must be sealed from the house air and the garage should be separately ventilated.

What are ERVs and HRVs?

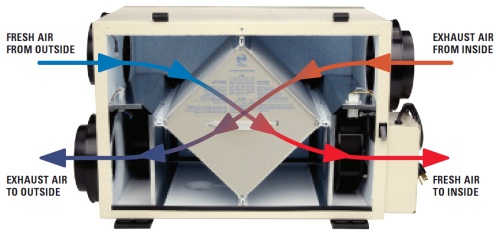

Both ERVs and HRVs have a heat exchanger that aims to somewhat match the temperature of the incoming air to the temperature of the outgoing air. ERVs go a little further in aiming to somewhat match the humidity of the incoming air to the humidity of the outgoing air. The matching process is obviously only possible to a certain percentage, but even so it can have a significant beneficial impact on your energy bill. In a top of the line ERV, they claim about 90% of the heat energy from the outbound stale air is transferred to the incoming fresh air (and about 70% of the humidity).

ERVs have a vapor-permeable membrane. Older ERVs use a wheel transfer but that tends to make them noisy.

HRVs and ERVs typically use DC variable speed fan motors.

ERV or HRV

If you are in a hot humid area then you will want an ERV, but if you are in a cold area then you are much better off with an HRV. HRVs are also a little bit more efficient than ERVs. My choice is an HRV.

Here's a quote from Martin Holladay at http://www.greenbuildingadvisor.com/blogs/dept/musings/hrv-or-erv : "If energy efficiency is your most important criterion — and I believe it should be —choose either the UltimateAir RecoupAerator 200DX ERV (which draws 40 watts to deliver 70 cfm) or the Venmar EKO 1.5 HRV (which draws 13.5 watts to deliver 40 to 80 cfm)." These are both very fine units, but you may decide to choose a smaller cheaper model such as a Fantech HRV that have starting prices of about $600.

Large UltimateAir ERV:

In my area it is necessary to heat the house for well over half the year, so any waste heat from the motor in the HRV/ERV will contribute towards heating the house during the cold months. Because of this I am a little less worried about how many watts the unit uses.

I ended up choosing Fantech HRVs because they were nicely priced. For my small evaluation building I used a "VHR70 Heat Recovery Ventilator w/ Recirculation Defrost, 4" Top Ports, 57 CFM" as it was only about $600 from SupplyHouse.com https://www.supplyhouse.com/Fantech-VHR70-VHR-70-Fresh-Air-Appliance-57-CFM .

The Fantech unit I chose for the evaluation building can only handle 1400 sqft so is not enough for my main house, but Fantech do provide low cost units that can handle many times that square footage (See full Fantech range at http://www.supplyhouse.com/Heat-Recovery-Ventilators-13180000 . Not a bad strategy is to use two lower price medium sized units to provide for your square footage because that means you still have ventilation if one of the units fails and needs to go off for repair. Having separate units in different parts of the house can also make the ducting easier. Having two units is what I decided to do for my main house.

Small Fantech HRV:

For the main house I use medium sized units. These use 6" ducts. Fantech SHR150 - VHR Series Heat Recovery Ventilator w/ Fan Shutdown Defrost, 6" Top Ports

https://s3.amazonaws.com/s3.supplyhouse.com/product_files/Fantech-VHR150-Install-Instructions.pdf

Info is here

.

Info is here

.

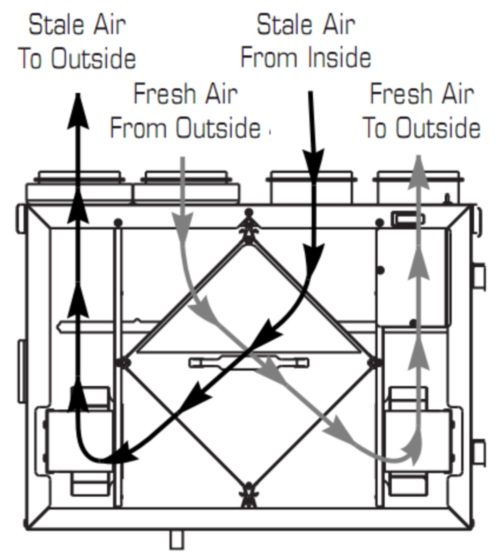

The other thing I like about HRVs is that they are nice and simple. There is a very obvious box like thing in the center. The box is a stack of plates that form alternating air channels. The stale exhaust air is on the even numbered airways and the incoming fresh air comes via the odd numbered airways (getting warmed by the stale air on either side). You can easily take the box out to clean it if it gets dirty or clogged.

A slight negative with a simple cross-flow diamond shape is the reduced efficiency caused by the temperature gradient across the path for the exhaust air. On the far side of the path the exhaust air will have cooled so cannot heat the inlet air taking that path across. Ideally the plates should have molded fin structures to produce lambda air flow.

Deciding CFM needed

Stale air exhausting

Kitchen 25 - 35 cfm (in addition to range hood

extractor fan)

Each bathroom 24 cfm

Half bath 20 cfm

Utility room

12 cfm

Fresh air inletting

Each person 18 cfm

Each bedroom

24 cfm

Each square foot X cfm

Calculate the inlet and exhaust cfms and then balance the system at whichever is the highest figure.

Optimum efficiency when inlet air cfm equals exhaust air cfm.

A 2,500sqft house typically needs about 100 cfm.

Ductwork

Duct size

A 3" pipe can go in a 2x4 stud wall but can only handle about 12 cfm. You can use two 3" pipes in parallel to get 24 cfm. I prefer 4" pipe so that one pipe can do 24 cfm.

Try to use 6" duct for as far as possible near the HRV. Use ridged ducting where possible.

Duct certification

King county and many other jurisdictions require ducting to be certified to UL 181.

UL 181 - Standard for Factory-Made Air Ducts and Air Connectors. https://standardscatalog.ul.com/standards/en/standard_181

PVC pipe is not UL certified but it is IAPMO certified. http://ww.iapmort.org/Pages/default.aspx . Need to talk with the building inspector if you are thinking of using it. The UL issue is about if there it is flame retardant (smoke spread rating) in the polyethylene. Since it carries air and connects multiple living spaces it is a valid concern.

Rigid duct

Where rigid duct is possible it provides better air flow than flexible. My preference is regular galvanized steel ducting from eg Lowes.

https://www.lowesforpros.com/pd/IMPERIAL-6-in-x-24-in-Galvanized-Steel-Round-Duct-Pipe/3134337

https://www.lowesforpros.com/pd/IMPERIAL-6-in-x-60-in-Galvanized-Steel-Round-Duct-Pipe/3482053

https://www.lowesforpros.com/pd/IMPERIAL-4-in-x-60-in-Galvanized-Steel-Round-Duct-Pipe/1000192521

https://www.lowesforpros.com/pd/IMPERIAL-6-in-x-6-in-Galvanized-Steel-Round-Duct-Elbow/1000227153

https://www.lowesforpros.com/pd/IMPERIAL-4-in-x-4-in-Galvanized-Steel-Round-Duct-Elbow/1000230213

These bend pieces are nice because they can adjust to any angle.

https://www.supplyhouse.com/Air-King-AK46R-AK46R-4-to-6-Round-Galvanized-Steel-Transition

Sometimes a diameter reducer is used on the side leg when you want a takeoff from the main trunk. Where you deliberately want less airflow in the takeoff leg it is good to use a 90 degree rather than a Wye.

Sometimes it is good to put insulation round the ducting, but my plan is to not bother initially and see how it goes.

https://www.lowesforpros.com/pd/IMPERIAL-4-in-Dia-Galvanized-Steel-Round-Damper-with-Key/50257175

Flexible duct

Where flexible ducting is needed, my vent preferred pipe is...

It is good to use some flexible duct to connect to the room outlet as this reduces acoustic noise.

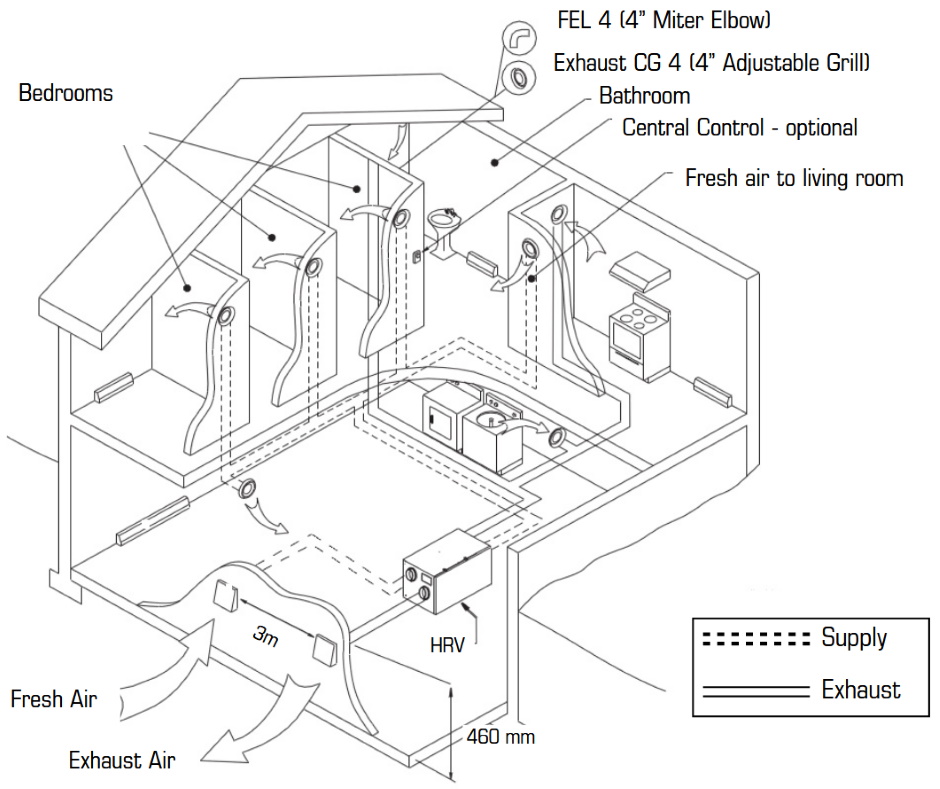

Exhaust from stale and wet areas, Fresh air to living areas

You need both an exhaust exit air path and a fresh air path. The exhaust exit air should be taken from bathrooms, kitchen, utility room, and from the top of the house living space (where old warm air will naturally rise to). It will be exhausted to the outside. Filtered fresh air from the outside should be gently blown into to the living rooms and bedrooms. In a balanced system (which is what you want) there is forced air on the exit exhaust and similar cubic feet per minute forced air on the intake.

External air intake and outlet locations

Obviously you want to site the air intake to be as far away as possible from anything generating pollutants such as a driveway or a sewer vent. It should ideally be at least 10 feet above grade on whatever side of the house you think has the cleanest freshest air. The inlet should be at least 10 feet from the inlet and up-wind of the prevailing wind.

Typically you will buy an inlet and exhaust pair, both 6" diameter.

Details

are

here .

Details

are

here .

Until the first bend (a 90 degree bend), the duct should be slightly sloped downwards so that any blown-in rain runs outside. After the first bend the duct will slope towards the HRV.

On the fresh air intake from outside it is good to have a filter box as close to the outside as possible to avoid bugs and dirt from getting into the inlet pipe. The following filter box is a good choice...

Details

are here .

Details

are here .

MERV filters

MERV ratings specify the efficiency of an air filter's ability to remove particles and pollutants from the air. MERV is the Minimum Efficiency Reporting Value. It's the scale designed by the American Society of Heating, Refrigerating, & Air Conditioning Engineers (ASHRAE) to give the effectiveness of air filters. A higher MERV rating indicates higher filtering performance.

A HEPA filter is often impractical in central HVAC systems due to the large pressure drop the dense filter material causes. Experiments indicate that less obstructive, medium-efficiency filters of MERV 7 to 13 are almost as effective as true HEPA filters at removing allergens but with much lower associated system and operating costs.

The recommended MERV ratings for residential filters are between MERV 7 and MERV 13. Filters with these MERV ratings perform as efficiently as true HEPA filters. They all trap the same range of particulates, particulates such as dust particles, mold spores, dust mite debris, tobacco smoke, pet dander, and pollen, but each filter has a higher capturing capacity the higher the MERV.

There are two different components of a MERV rating. First is the ability to remove large airborne particles, ie particles that are between 1 and 10 microns. These “large” particles include pet dander, pollen grains, dust mite debris, etc. The bulk of indoor air pollutants however are in a smaller size range. MERV also rates the filter’s ability to remove submicron particles, ie those that are smaller than 1 micron - this rating is called the Microparticle Performance Rating (MPR), and some filters are given just this rating.

MERV 13 rated filters have a dust spot efficiency of 80-90% and they are highly efficient filters both for residential and commercial use. MERV 13 filters remove a higher range of particulates, including larger amounts of bacteria and even some viruses, and they are best for people suffering from breathing problems. Also, despite their high capturing capacity, they still maintain a low resistance to airflow.

HEPA filter

High Efficiency Particulate Air filter. To qualify as a HEPA filter by US government standards, an air filter must remove (from the air that passes through) 99.97% of particles that have a size of 0.3 µm.

HEPA filters typically restrict air flow more than MERV-13 filters.

The term HEPA is a more well known marketing term for filters.

As a general approximate rule of thumb, a filter that is rated as MERV-13 is equivalent to a HEPA filter in it's ability to clean the air, but a MERV-13 filter will allow a greater CFM air flow, ie will produce less pressure drop. A HEPA filter will take out more 0.3 micron particles in one pass, but a MERV filter will allow much more air to pass through and thus will get rid of the 0.3 micron particles in the multiple passes that more air flow provides.

Where to site the ERV

Putting an ERV in the basement is the most common location. It needs to be in a heated part of the house to avoid condensation issues. HRVs/ERVs do make some small amount of noise so it wants to be sited away from rooms where you want quiet. It also has some slight vibration.

I use two HRVs (each 150cfm). Both are in the basement. One is in the west area and one in the east area.

West Basement HRV:

Stale air from:

Mudroom bathroom (high vent)

Mudroom (near wood fire) (high vent)

Kitchen range hood (high vent)

Utility room (high vent)

Main level family bathroom (high vent)

Fresh air to:

Basement east

(high vent)

Basement

center (high vent)

Living room (low vent)

Kitchen (low vent)

East Basement HRV:

Stale air from:

Cupola

Bedroom level

family bathroom

Her master

bathroom

His master

bathroom

Fresh air to:

Living room

Master bedroom

Bedroom 2

Bedroom 3

Stale air ductwork

Vents to extract air from damp rooms such as bathrooms, kitchens, and utility rooms should be in the ceiling or at the top of the wall in that room (because warm air rises). Once it has safely got to the stale air pipe, the fan will take it to the HRV ok. In the kitchen, think about how best to avoid the stale air pipe picking up vaporized grease (eg if ceiling height allows, keep it 8 feet above the actual cooking surface). A filter on the stale air intake grill in the kitchen is also a possible idea (but I'm not doing this).

Details

are here .

Details

are here .

If you just put a filter on the extraction duct from the kitchen and not on the other extraction ducts then the proportion of stale air coming from the kitchen will be reduced. You could put filters on all the intakes, but in practice just one filter box near the HRV/ERV is all that is needed. It is a benefit to have a separate filter box on the stale air into the HRV/ERV because there is a filter box on the fresh air intake from outside and so it is good to provide a similar restriction on the exhaust so the system is well balanced.

Intakes for stale air to the HRV can be provided both high and low in a room. In the winter you open the bottom vents (and close the top) and in the summer you open the top vents (and close the bottom). Personally I always just put the stale air intakes high in a room.

Fresh air ductwork

You want to have fresh air provided to all the rooms where people sit or sleep. The vents providing fresh air should be sited to avoid drafts. An appropriate spreader vent (as pictured below) will help avoid drafts. Typically they are high on the wall.

Details

are here .

Details

are here .

The above pictured vents look quite stylish and can also be used as stale air intakes.

Use a tight turn 90 degree 4" fitting to install behind the wainscoting. Cut 3/4" off one of the ends of the fitting to get the vent unit to sit against the outside of the wainscoting wood.

Fresh air feeds typically require the 4" PVC pipe to come up vertically through the concrete floor from the ceiling of the floor below.

Ductwork implementation

You need ductwork that is as smooth as possible inside. Whenever possible, use long turn 90 degree bends or two 45 degree bends so that air flow is not too restricted.

Route it to avoid condensation, ie slope it downwards towards a drain. That means the HRV needs to be lower than the stale air vents that go to it. Insulate around it if routing through a cold area. If the vent pipes slope down to the HRV then insulation is not required because condensation water will come out of the HRV drain. Also uninsulated pipe takes less space in the wall/wainscoting.

The 4" ducts for the fresh air to the rooms and stale air from the rooms needs to be primarily routed in the ceiling. Typically the vents and the ducting will be incorporated into the soffit light assembly.

The ducts should ideally to be routed with a downward slope to the HRV so that condensation flows to the HRV and then out of the HRV's drain.

If an HRV is in the basement then the fresh air vents can be low down on the main level walls above. For a bathroom in the basement it is necessary for the stale air duct to go up hill.

Clothes dryer

Use a heat pump clothes dryer rather than feeding the dryer exhaust into an HRV. It would clog an HRV with water and then the dryer will burn out because it cannot vent.

Kitchen cooktop extractor hood

Building code

Building code specifies a minimum height and also says follow manufacturer's spec for the height.

M1503.1 General. Range hoods shall discharge to the outdoors through

a single-wall duct. The duct serving the hood shall have a smooth

interior surface, shall be air tight and shall be equipped with a

backdraft damper. Ducts serving range hoods shall not terminate in an

attic or crawl space or areas inside the building.

Exception: Where

installed in accordance with the manufacturer’s installation

instructions, and where mechanical or natural ventilation is otherwise

provided, listed and labeled ductless range hoods shall not be required

to discharge to the outdoors.

SECTION G2447 (623) COOKING APPLIANCES G2447.1 (623.1) Cooking

appliances.

Cooking appliances that are designed for permanent

installation, including ranges, ovens, stoves, broilers, grills, fryers,

griddles, hot plates and barbecues, shall be tested in accordance with

ANSI Z21.1 or ANSI Z21.58 and shall be installed in accordance with the

manufacturer’s installation instructions.

G2447.5 (623.7) Vertical

clearance above cooking top.

Household cooking appliances shall have

a vertical clearance above the cooking top of not less than 30 inches

(760 mm) to combustible material and metal cabinets. A minimum

clearance of 24 inches (610 mm) is permitted where one of the following

is installed:

1. The underside of the combustible material or metal

cabinet above the cooking top is protected with not less than 1/4 inch

(6 mm) thick insulating millboard covered with sheet metal not less than

0.0122 inch (0.3 mm) thick.

2. A metal ventilating hood constructed

of sheet metal not less than 0.0122 inch (0.3 mm) thick is installed

above the cooking top with a clearance of not less than 1/4 inch (6 mm)

between the hood and the underside of the combustible material or metal

cabinet. The hood shall have a width not less than the width of

the appliance and shall be centered over the appliance.

3. A listed

cooking appliance or microwave oven is installed over a listed cooking

appliance and in compliance with the terms of the manufacturer’s

installation instructions for the upper appliance.

Typical CFM

A typical cooktop can require 500 CFM or higher. Some people recommended an additional 100 CFM for every 3" above 2'6" (above cooktop).

Even if the HRV was dedicated to the cooktop it would only provide 150 CFM extraction. A non dedicated HRV stale air vent would be more like 24 cfm.

My requirements

Don't waste heat by extracting directly to the outside.

Hood to be as high as possible so that fat particles don't get sucked into the HRV.

If it sticks out a long way then make it above 6'6" so nobody hits their head.

As there does not seem to be a building code requirement on the front to back dimension of the hood, just make it the same distance as the upper kitchen cabinets. In fact just make it look like another wood door kitchen cabinet. If it does not stick out far then there is no danger of banging your head to it does not actually need to be any higher than all the other upper cabinets. It does still need to be more than 30" above the cook top if it is made of wood.

Does not generate noise.

Not likely to drop dust into the food.

A way of getting rid of smoke quickly if food burns.

My conclusion

Make a large hood from wood that looks nice. Make it 6'6" from the floor. This is 3' above the cooktop, ie is more than 30" so wood is allowed.

Have two vent pipes from the top of the hood - one to the HRV and one that goes direct to the outside via a sealed backdraft damper and an inline fan. The fan will only be turned on in the event that the cook causes lots of smoke that you need to get rid of quickly (without worrying about building heat loss).

Ideally there would be two electrically operated dampers. When the extractor manual emergency switch is operated, the vent path to the HRV would close and the vent path to the outside would open (and the fan would come on).

Duct damper

electrically operated

Duct damper

electrically operated

The hood is designed to look like regular kitchen cabinets. The cabinets will be shallow because there will be a wooden back set well forward. A rectangle of chunky wood provides the mouth above the cook top on the underside of the cabinet style hood.

Supe it up with an after-burner

It's not actually an after-burner (although that name makes it sound cool), but it is a good idea to provide the ability to heat the intake air.

May as well heat incoming air

I'm not a big fan of forced air heating, but given that you need to deliver fresh air to the various living rooms and bedrooms you may as well on cold days heat it up a bit. At the very least it's good to take the chill out of it so room occupants don't get any cold drafts.

Details

are here .

Details

are here .

It is installed on the house side of the HRV (near the HRV) on route to the fresh air vents for the rooms.

No forced air furnace

In my case I am not using furnace driven forced air heating. It is electrical heating, but in my area electric power is not too expensive and I don't have natural gas available. An after-burner on the fresh air delivery contributes to the electrical heating for the house.

Note that for a well designed heating system it is necessary to have a combination of warmed fresh air and air that is recirculated and heated. You will not be able to economically keep your house at a comfortable temperature by only doing heating of fresh air. You need some heating that takes air from within the house, heats it, and then returns it to the rooms.

Shutters on some fresh air vents

If there are some rooms of the house that are sometimes not used, then it's not a bad idea to shut-off those fresh air vents so that the heated fresh air is not wasted on those rooms. You want the warm fresh air to be mainly going to where the people are. In the primary living room and primary bedroom(s) it is best to not provide a shut-off mechanism so the HRV/ERV always has somewhere to send the warmed fresh air. The vents I'm using are adjustable so you can close up the vents in rooms that are not being used.

Details

are here .

Details

are here .

Air flow and filtering

Required air flow

A good rule of thumb is to say that you should have an ERV/HRV system that can provide 0.05 CFM for every square foot of finished space in your house. A house of 4,000 sqft would therefore need 200 CFM. Even if on a bigger house you install just one then you should implement the ductwork to allow another to be added later. I'm using two HRVs that each are 150cfm, which is a total of 6,000 sqft.

Air filtering

Most HRVs and ERVs provide both ventilation and filtration. It captures pollen and mold spores before fresh air is passed into the house. Even with this (as noted above) it is good to provide a separate filter box on both the fresh air intake and the where the stale air enters the HRV/ERV.

Details

are here .

Details

are here .

You need a filter box on the stale air duct as well as the fresh air duct. As well as stopping dust from the house clogging up the HRV it also helps equalize the input and output pressure.

With my two HRVs, that means I have 4 filter boxes.

You should plan to replace the filters about every 3 months.

Is a separate de-humidifier needed?

It is possible in humid or wet climates, or when having lots of showers or boiling lots of pasta, that you might need a separate de-humidifier unit. The likelihood of needing a de-humidifier is slightly reduced by choosing an ERV instead of an HRV, but there is still the possibility of needing a de-humidifier. My advice is to monitor the humidity over the first 6 months of living in the house, and then decide whether or not to get a de-humidifier.

Other HRV/ERV brands

I decided to use Fantech HRVs (as detailed above for price reasons), but here are details of other good choices.

UltimateAir

178 Mill Street, Athens, Ohio 45701.

740-594-2277

www.UltimateAir.com info@ultimateAir.com

Jason Morosko jmorosko@ultimateair.com

Airflow Capacity: ~70 – 210 CFM

Dimensions: 25 in. H x 19 in. W x 25 in. D (63.5 cm H x 48.25 cm W x 63.5 cm D)

Uses 6" duct (but output from inline heater option is 8").

The retail price is close to $2000.

Air circulation and filtering

My house has something of a chimney effect because it is a tall building with stairway openings between each floor. It is good to suck hot air from the top of the building and pump it down to the bottom of the building.

To reduce general dust in the air it is good to recirculate air via a filter eg a MERV-13 filter.

Combining the two needs leads to the following solution...

I run a 6" air vent pipe from the attic (where the hot air rises to) down to the basement. Inline with the pipe is an 8" duct fan (with 8in/6in reducers) and a filter box.

Filter

box details

are here .

Filter

box details

are here .

https://smile.amazon.com/gp/product/B01C82T0QC/ref=oh_aui_detailpage_o03_s00?ie=UTF8&psc=1 $25.99

https://smile.amazon.com/gp/product/B00B6K6NZO/ref=oh_aui_detailpage_o01_s00?ie=UTF8&psc=1 $11.77

Adding air conditioning and heating heat pump

If you want air conditioning with the added benefit of using a heat pump to provide some efficient heating then after the ERV/HRV it is good to add a unit such as the Sanyo unit pictured below. There is an outside unit that can be placed well away from the house and this connects with up to 165 feet of refrigerant piping to the inside unit that can be placed inline with your ERV output ducting. Expect to pay about $4K for this system, eg from http://ecomfort.com/31200-btu-36pef1u6-concealed-duct-ductless-heat-pump-system-28475.html .

Even if you do not put in air conditioning (and I'm not planning to do it because I just rely on all the thermal mass) it is a good idea to allow room for the possibility in your ducting system.

Clothes Dryers

There are three types... Vented, Condensing and Heat Pump. My recommendation is to get a Heat Pump clothes dryer.

Vented dryers

These use electricity or gas to generate heat and then exhaust the hot moist air to the outside (loosing all the heat energy). These are the conventional cheap type of clothes dryers. Building code requires proper exhaust venting.

Condensing dryers

The main focus of these is to remove the need for exhaust ducting rather than to save energy (although they do save some small amount of energy).

Heat pump dryers

A heat pump dryer captures the hot air, removes the moisture from it, then reuses that already hot air to dry more clothing. The technology is already reasonably common in the rest of the world, but eg LG's EcoHybrid is actually the first heat pump dryer commercially available in the United States. The price for this model (number DLHX4072) is about $1,600.

They’re much more efficient than traditional condensation dryers (40-50 percent by some estimates).

Building code

IRC 2003, Section M1501 Clothes Dryer Exhaust M1501.1 General. Dryer exhaust systems shall be independent of all other systems, shall convey the moisture to the outdoors, and shall terminate on the outside of the building. Exception: This section shall not apply to listed and labeled condensing (ductless) clothes dryers.

IRC 2003, Section P3001, General The provisions of this chapter shall govern the materials, design, construction, and installation of sanitary draining systems. Plumbing materials shall conform to the requirements of this chapter. The drainage, waste, and vent (DWV) system shall consist of all piping for conveying wastes from plumbing fixtures, appliances, and appurtenances, including fixture traps, above-grade drainage piping, below-grade drains within the building (building drain), below-and above-grade venting systems, and piping to the public sewer or private septic system.

IMC 2003, Section 504 Clothes Dryer Exhaust, Section 504.1 Installation Section 504.1 Installation. Clothes dryers shall be exhausted in accordance with the manufacturer's instructions. Exception: This section shall not apply to listed and labeled condensing (ductless) clothes dryers.

If a condensing dryer or Heat Pump dryer is specified, verify that the proper drainage or an adjacent sink has been provided to remove the condensate.