Home Site Map - Techniques - Interior Design -

Interior Design General

![]() Decide on the look you want to achieve and develop a consistent

design syntax.

Decide on the look you want to achieve and develop a consistent

design syntax.

Intro

It is good to try to get some consistency with the interior design. Try to establish a limited set of ways of doing things. This is the design syntax.

You need to have somewhere to route the wiring and you need to have room to mount the power connectors and Cat-6 connectors, as well as route water pipes and ventilation pipes etc. My solution to this is to implement a 1' 6" high (above finished floor) wainscot. That gives a 5-1/4" wide channel for routing.

The wall above the wainscot is the 1/4" plywood of the Carnation Walling with a thin skim of interior stucco over it.

At the top of the of the wall a large cornice made from hot-wire cut polystyrene is used to provide a place for the up-lighting. This has stucco sprayed onto it.

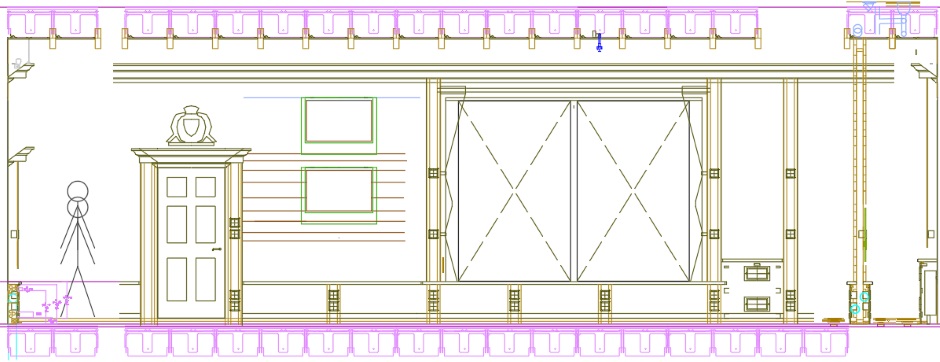

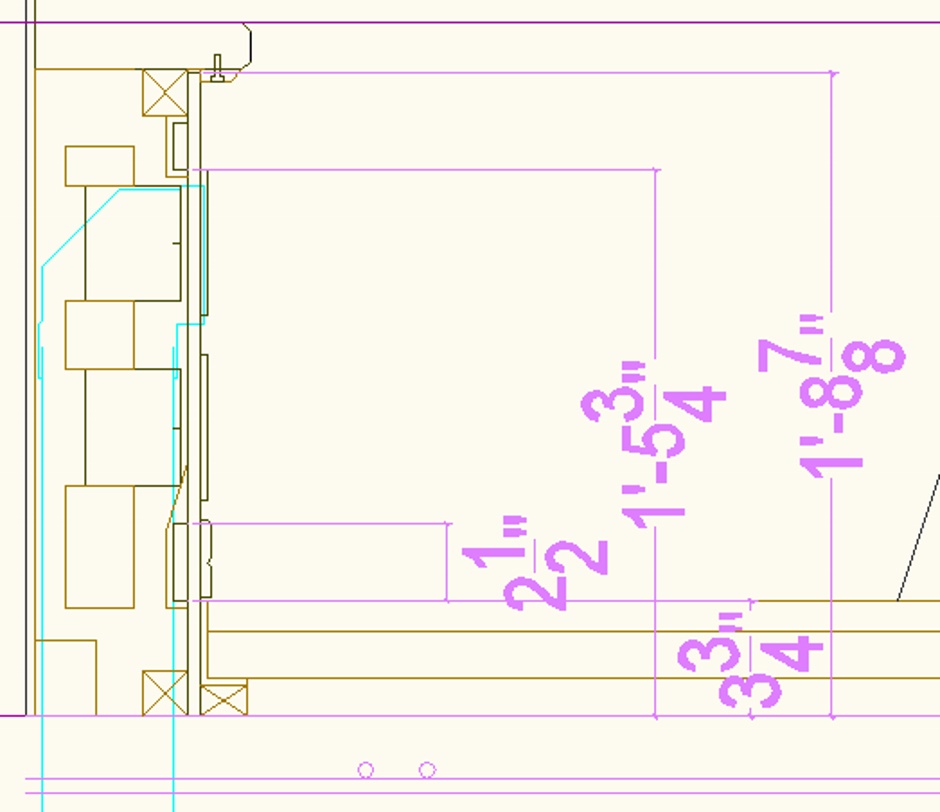

Master diagram

An important thing to have is a CAD drawing that sets your dimension standards. It sets things such as the height that your wainscoting and electrical sockets will be from the floor. You don't want this to vary or it will look weird.

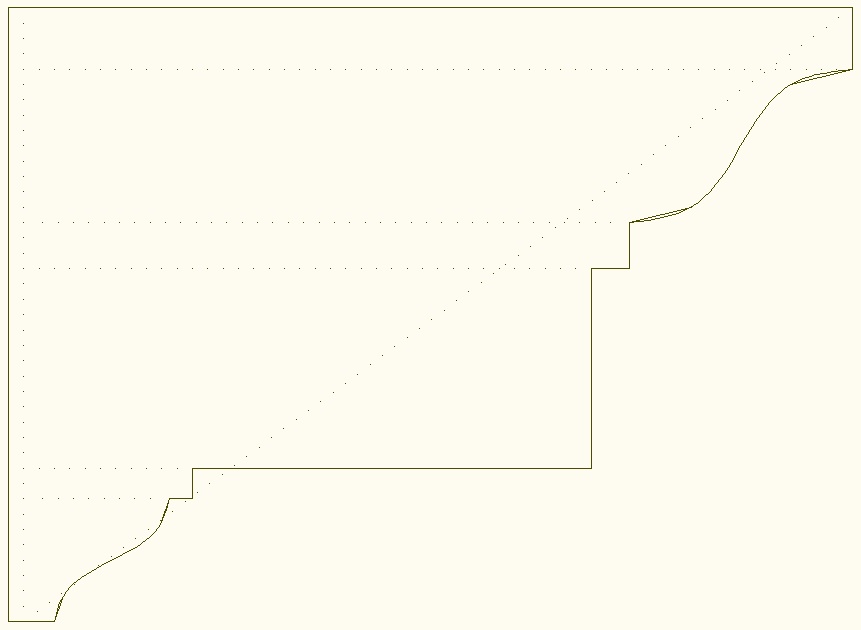

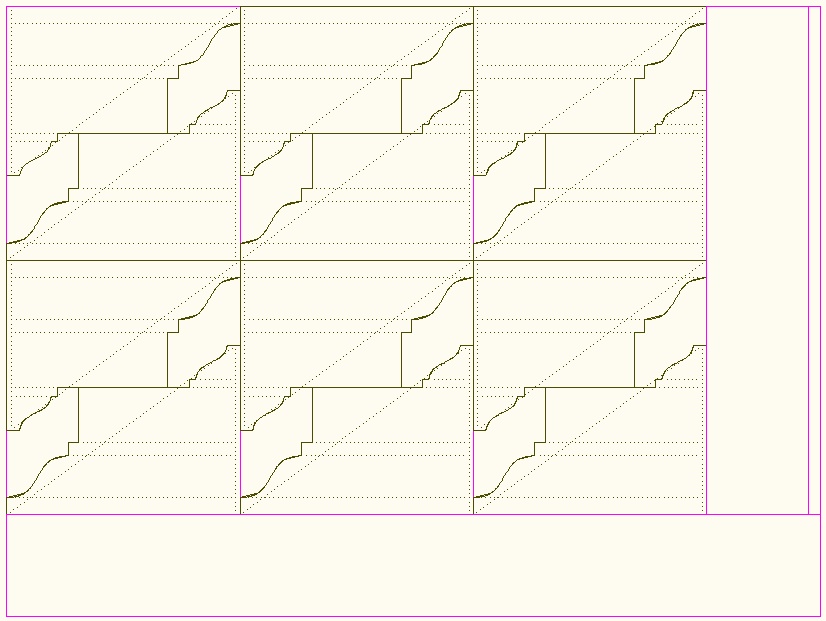

Cornice

Cornices are made from Expanded Polystyrene CNC hotwire cut to a specific profile. The size and profile is the same as used for the cupola and above the windows on the building exterior. They can also be used above internal doorways (given the high ceiling heights).

The width is 1' 1-3/4" and the height is 10".

These are cut from an EPS ingot that is 4'x3'x8'. It leaves some 6" thick EPS sheets as offcuts.

The cornice profile is also a good choice for a mantle above the fire place in the living room. In the case of a fire you do not want it to be made of polystyrene, so you can instead use the EPS offcuts glued to the second EPS cornice piece to make a mold for concrete.

Wainscot

The wainscot provides 5-1/4" of space for routing ducting and wires.

The wainscot 3/8" facing wood is held in place by thumb screws at the top (and to some extent by the electrical faceplates). This approach means that during house construction and potentially during the first year or two of house occupation it is possible to remove the wainscot front face wood to run additional wires and pipes.

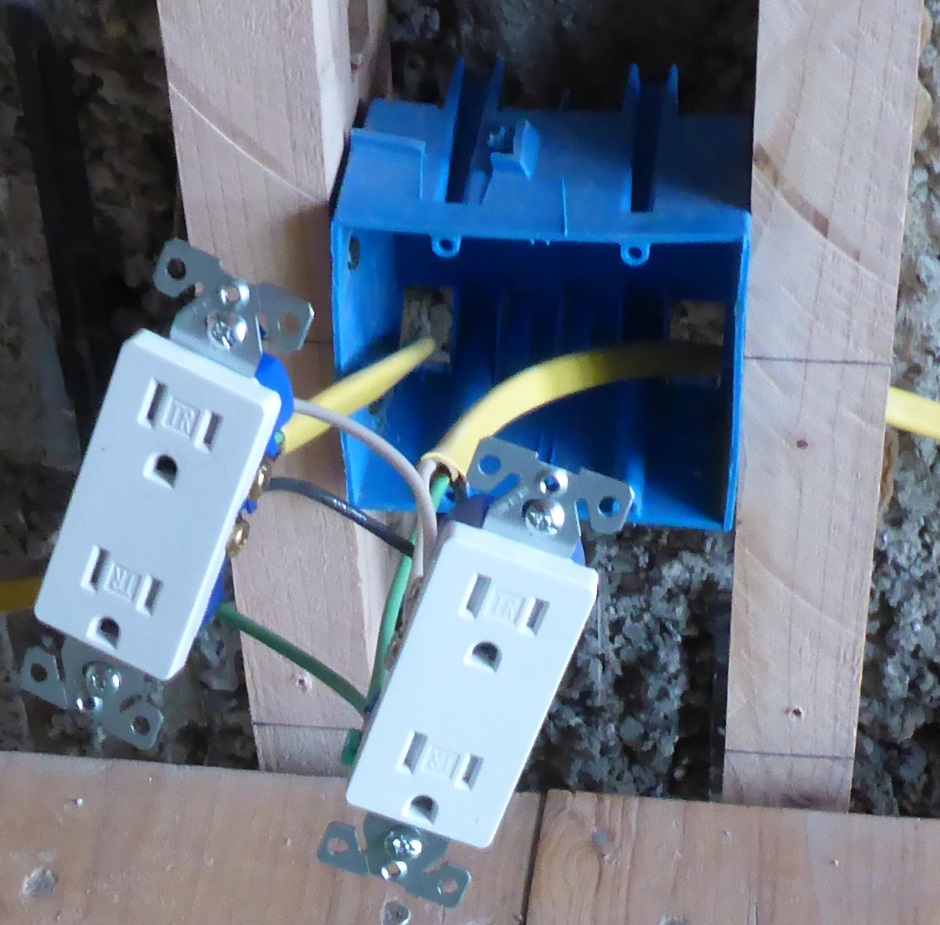

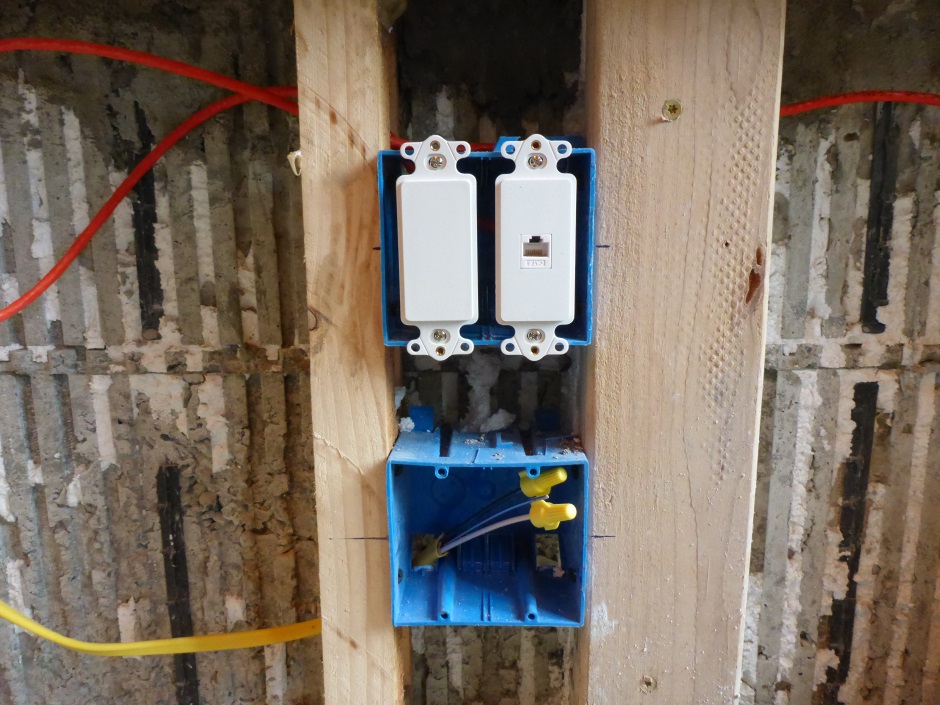

Double width electrical boxes are used throughout (both for power sockets and Cat6 etc), even if it means one position has a blank insert. They are at a standard height as shown on the CAD drawing. (When the electrical box height was determined and standardized, it allowed for the raised height of the flooring.)

Wainscot height

The height of the top of the wainscot from the floor ideally should

correspond to the height of the pedestal of a column that is the height

of the room. What this translates to is the following formula...

Room height in inches / 13 * 2.67 (and then round it down slightly).

My main floor has a ceiling height 12 feet which is 144 inches, so the wainscot should be 2' 5-1/2".

My bedroom ceiling height is 10 feet which is 120 inches, so the wainscot should be 2' 0-1/2".

My basement ceiling height is 14 feet which is 168 inches, so the wainscot should be 2' 10-1/2".

In practice in my case the wainscot is lower because it is determined by the height of the window sills below the big windows. For me the top of the wainscot wood shelf is 1' 10-1/2" from the concrete surface, which is 1' 7-1/2" from the finished floor.

Spacer posts

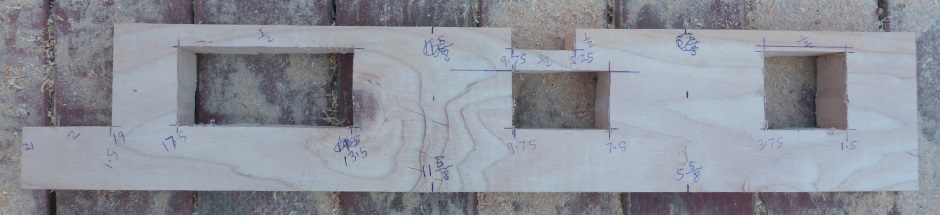

For concrete walls (that do not have wood studs), wooden spacer posts are glued to the wall either side of where the electrical boxes are positioned. They have three holes in strategic places to allow wires to be routed. Typically low voltage wiring is routed through the top hole and power wiring through the lower hole.

Also marked on the spacer posts are the standardized positions for the electrical boxes. The usual electrical box is centered 11-5/8" from the underside of the wooden shelf (ie the top of the spacer post). There is room for eg an electrical box for a cat-6 socket above the electrical box (centered 5-5/8" below the underside of the shelf, ie 6" above the usual electrical box).

The spacer posts are 5" wide and are glued (using PL-Premium) to the plywood of the concrete wall.

You can use a 4" wide spacer while the spacer posts are being glued.

The shelf is glued to the top of the spacer posts (using PL-Premium)).

Once the electrical boxes have been fitted and the shelf glued on, you can measure everything to produce a hand drawing of the piece (or pieces) of wainscot facing wood needed to cover everything. If you are uncertain of the measurements then make the electrical box holes small initially and then enlarge them later.

The holes in the wainscot plywood are cut big enough at the top and the bottom such that the wainscot facing wood just fits over the installed electrical sockets. Don't make the hole any bigger than necessary because the hole needs to be covered by the electrical faceplate.

Tongue and groove facing wood

This is only 5/16" thick (call it 3/8"). This will look nicer than using MgO drywall or thin plywood.

5/16 in. x 3-1/8 in. x 96 in. Northern American Knotty Pine Tongue and Groove Wainscot Paneling $6.16

The horizontal planks top and bottom can be done by rip cutting the same planks.

Each foot of wainscotting will cost about $8 (which is not too bad).

There are dummy joins between the actual joins which makes it look nicer.

Floors

Standard floor and wainscot height

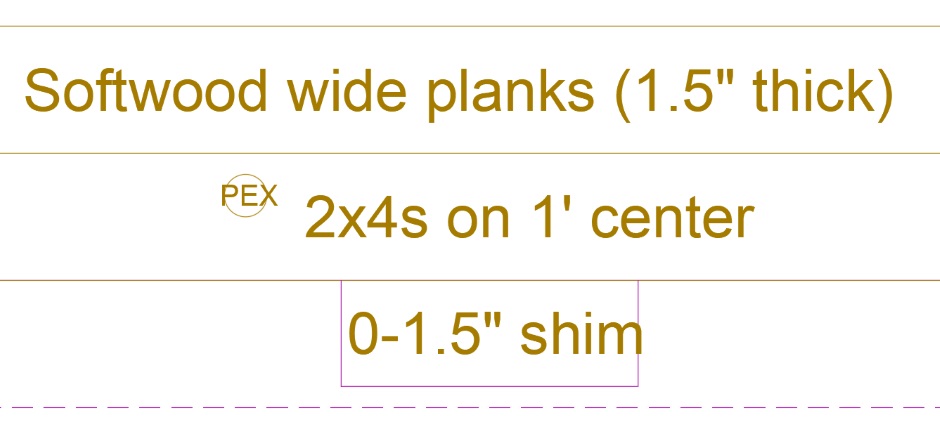

The wainscot height is actually implemented all the way up from the structural concrete slab/floor. The standard height for the finished floor above the reference (highest point) on the structural concrete slab is 3". In practice there are lots of ways that the flooring will be done in different rooms. Sometimes it will be tiles, sometimes a self leveling concrete topping layer, sometimes 3/4" hardwood flooring, sometimes my own cut softwood. Sticking to a standard height avoids floor level transitions (which are a tripping hazard).

Floor leveling

It is assumed that the structural concrete slab will be level to within +/-5/8", ie a min to max variation of 1.25". The reference, ie what constitutes the bottom of the vertical wall batons, is set to be the highest measured point on the poured slab. That means that 1.5" x 3.5" shims of between 0" and 1.25" will be used. The finished floor level will be 3" above the reference.

The required shim height is determined using a self leveling laser and a graduated target to find how far below the reference the surface of the concrete is at each point.

Typically a layer of 1' on center on-flat 2x4s is used above the spacers to provide a 1.5" cavity for routing the PEX radiant heating pipes and any wires that might be needed. In practice the cavity with often be more than 1.5" because of the shims, but the minimum cavity height will be 1.5".

Floor gluing

The shim wood and cavity wood will be glued in place with PL-Premium. Use paving slabs to weigh down the 2x4s while drying.

In the case of softwood flooring, the planks will be glued to the cavity lumber using PL-Premium. Use paving slabs to weigh down the planks while the glue dries.

Water radiant heating

PEX pipe is routed in the gap between the 2x4 planking. The 2x4s are 3/4" short near the walls to leave a gap for the PEX. The 2-by-4 planks are 1 foot on center. This comfortably bigger than the smallest arc diameter (10.5") that you can bend 1/2" PEX pipe.

Plastic body staples are used to attach the PEX pipe to the side of the glued 2x4s.

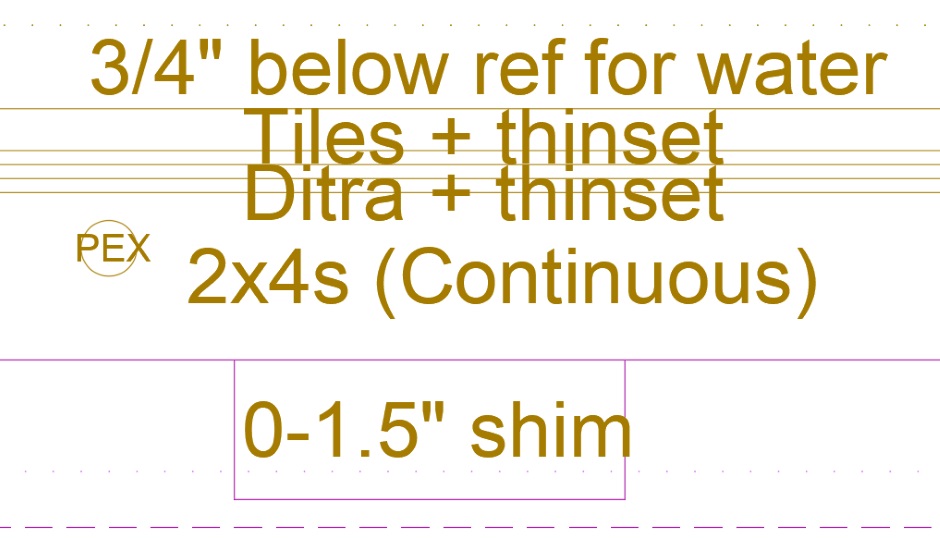

Wet rooms

In the case of a bathroom that is designed to be a full wet room it is best to deviate from the floor standard height and make it 3/4" lower. This means the water will go down the floor drain rather than spill out of the room. You will need a height transition of about a tile width (12") as you come through the door.

Between house levels

It is not the case that concrete slab heights can be treated independantly between the different levels of each house, eg basement to main level. Each house level is connected by stairs and therefore the rise between floors needs to be accurate.

The following gives how the standard height will be achieved for the different flooring types...

Chosen cases

Softwood floor (PEX radiant heating)

0 - 1.5" Air gap of between 0"-1.5" to take out slab height variations.

1-1/2" 2-by-4 lumber with

PEX radiant heating pipe on side. 1' on center.

1-1/2" Softwood planks.

Tiled floor (PEX radiant heating)

0 - 1.5" Air gap of between 0"-1.5" to take out slab height variations.

1.5" Continuous

surface of 2-by-4 lumber with PEX radiant heating pipe in groove.

1/8"

Thinset to hold Ditra.

1/8"

Ditra

1/8" Thinset to hold

tiles.

3/8" Porcelain

tiles.

3/4" 3/4" lower

than the reference to allow water containment

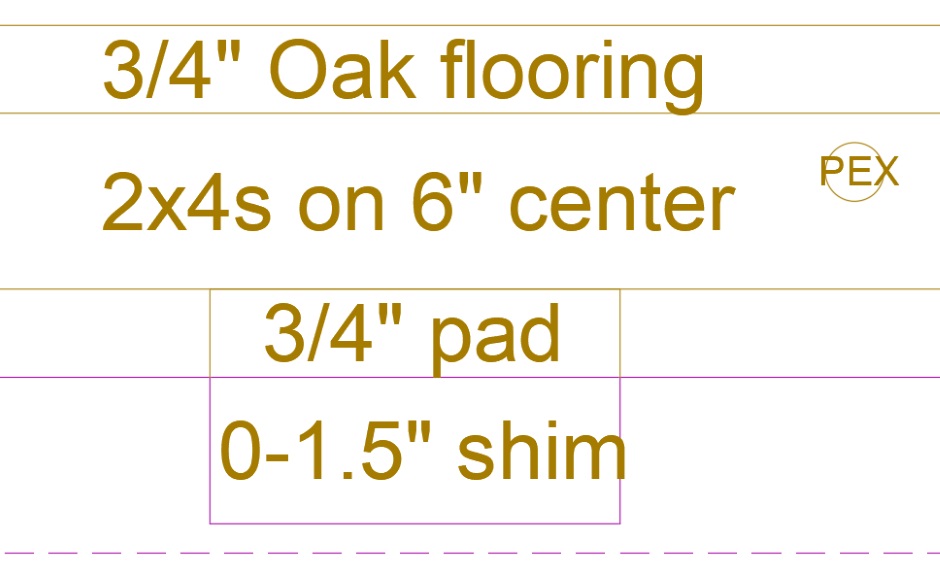

Hardwood floor (PEX radiant heating)

0 - 1.5" Air gap of between 0"-1.5" to take out slab height variations.

3/4" Padding of 3/4" which is

done by adding 3/4" to the shim height.

1-1/2" 2-by-4 lumber with

PEX radiant heating pipe on side. 6" on center.

3/4"

Hardwood flooring.

Less common cases

<Update these to reflect 3" floor height>

Self leveling concrete floor (PEX radiant heating)

1/2" Air gap of between 0"-1" to take out slab height variations.

1-1/4" Additional air gap.

1-1/2" 2-by-4 lumber with

PEX radiant heating pipe on side.

1/2"

Self-leveling concrete.

Softwood floor (electric radiant heating)

1/2" Air gap of between 0"-1" to take out slab height variations.

3/8"

Additional air gap.

1-1/2" 2-by-4 lumber.

1/8"

Thinset to hold heating mat.

1/8"

Electric heating mat.

1/8" Thinset

to protect heating mat.

1"

Softwood planks.

Tiled floor (Wooden mezzanine )

Floor is sloped towards drain, so only the edges are at 3-3/4 standard height.

At the door the floor height needs to be 3.75". As the Ditra tiles and thinset are 0.75", that means wood threshold at door is 3".

1.5" - 3" Concrete/mortar

1/8"

Thinset to hold Ditra.

1/8"

Ditra

1/8" Thinset to hold

tiles.

3/8" Porcelain

tiles.

Internal walling

Different types of internal walling are used depending on the need. All walls will be constructed using 2x4 studs. The outer sheeting on the wall varies according to the need and can be different on each side. Typically the sheeting is 1.5" thick. Sometimes EPS is used in the wall cavity to provide sound insulation and support for the (EPS) sheeting.

Wainscoting is used for cases where access is needed or plumbing routing or power sockets (to ensure no power socket is more than 6' away).

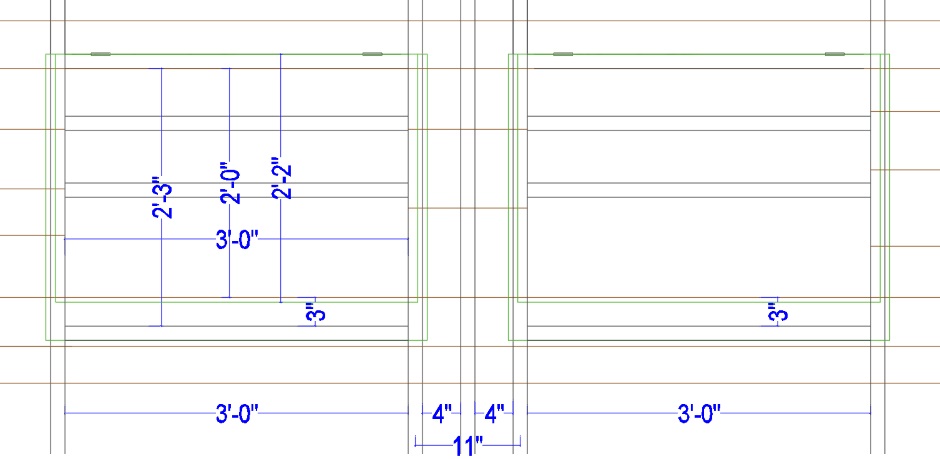

Stud algorithm

This determines where the vertical studs in the internal walls are positioned.

There is a good argument for framing to provide 3' rough openings for doors and for canvas pictures. Where possible and appropriate, put studs 3' 1-1/2" on center. Between the 3' rough openings put twin studs that are 11" on center (with an extra small height stud between them to support electrical boxes when needed). If necessary you can make the twin full studs 5.5" on center, but visually this makes the gap between pictures smaller than ideal. The 11" on center allows for two 4" gaps for electrical boxes lower on the wall. Adjacent to a door it is good to have a 4" rough opening between studs for double electrical switches.

Wood planking

Horizontal planks of 1.5" thickness of variable width.

If using fresh sawn wood from the forest, the planks need to be allowed time to dry and shrink before being fixed in place.

There is no need for wood planking behind where canvas photo is installed. This allows shorter pieces of wood to be used (which are easier to haul from the forest).

Depending on what is used on the other side of the wall, it is sometimes necessary to include a layer of eg black paper ( https://smile.amazon.com/Pacon-67304-Spectra-ArtKraft-Duo-Finish/dp/B00006IE1U/ref=sr_1_5?keywords=black+paper+roll&qid=1584116243&sr=8-5# ) to stop being able to see through.

Joins between planks that are too short can be avoided by using pilasters and making the planks long enough to go between them. Pilasters have white sides and thin wainscot wood on the front.

It is nice to make one or more walls in a room from wood planks as it is a nice accent and makes the room feel cozier. Note that this implementation is only applicable on internal walls and typically most rooms have one or two concrete walls that will be white plastered.

The wood feature walls can be rough cut un-sanded wood to give some texture. No need to varnish the wood.

They will be held on using 2.5" chrome Kreg screws (which have a reasonably decretive head). If the wood dries and shrinks then the screws can be undone and the gaps between the planks can be closed before re-screwing.

Initially just put wood on the most visible side and fit pipes etc from the other side.

Tiled EPS

High density (40psi) 1" thick EPS. Use 6mil polyethylene sheeting under the EPS so no water reaches the wood studs. No need to use Kerdi on the EPS - just glue on the porcelain tiles with foam adhesive and the grout with epoxy grout.

Between the studs to fill the cavity will be EPS, one sheet of 2" and one of 1.5". Glue it in place with foam adhesive. The cavity EPS provides support for the 1" EPS sheeting and provides soundproofing.

Firewall

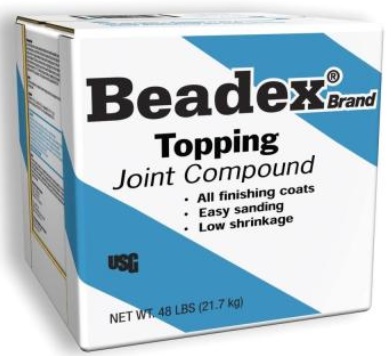

Use two layers of 5/8" drywall. Use drywall that is Greenguard "children and schools" certified (even though this is still not great as it still has power station synthetic gypsum). Stagger the joints in the drywall to ensure no path through. Use drywall mud to make it air tight (and/or firestop rated foam gap filler). Use Beadex as a surface coat if needed.

The other side of the 2x4 studding can have any sheeting type because the fire rating is all done on one side.

Typically, eg for the garage wall, the firewall will also have EPS insulation in the core. Even though the garage is within the house thermal envelope you still want to limit heat loss when the big garage doors are open.

No sheeting

In some circumstances, eg inside a pantry or clothes cupboard, it is ok to have no sheeting on one side of the 2x4 framing. You can add pieces of horizontal 2-by between the studs to make shelves.

Stuccoing

In the area between the top of the wainscoting and the cornice, I decided to use a thin skim layer of Beadex as the wall finish. It is necessary to fill the tie rod holes first.

I searched long and hard for the most healthy stucco to use. Even clay earth stucco contains silica. Some clay is just as bad as concrete from a silica % perspective.

There's a good website here .

In the end, this is what I settled on using...

For the bulk fill areas such as the 45 degree edges of windows, just use regular Sakrete concrete mix. Like all concrete it unfortunately has lots of silica, but at $3 per bag it is a cheap fill. For smaller fill areas use type S mortar.

For the top coat, use the lowest silica content plaster you can find. That will be less than 5% by weight in the legal MSDS document and in the description is called "trace amounts of silica" or "percentage weight not measured". The one I chose was Beadex Topping Pre-Mixed Joint Compound.

Details are here .

Details are here .

Steps

1) Fill in the big voids with Sakrete concrete mix. It is used to make the 45 degree edges on either side of the windows. Applying it with your hands (wearing neoprene gloves) works well. Use a cut wooden scraper jig to form the 45 degree angle.

Details are here .

Details are here .

2) Apply the scratch coat of stucco mortar that is used for filling in smaller fill areas and getting a basically flat surface. Applying it with your hands (wearing neoprene gloves) works well.

3) Apply the second coat (called the brown coat) to make a nice flat surface for the wall. Typically a nice long magnesium mortar float is used to get it flat and smooth.

4) Apply Beadex Topping Pre-Mixed Joint Compound. Use a long trowel to get it smooth.

5) Finally the wall is painted with latex paint to seal it.

Electrical boxes

These want to all be at a standard height. Personally I like them to be low down, just above the level of your highest floor. For the standardized height look at your CAD drawing.

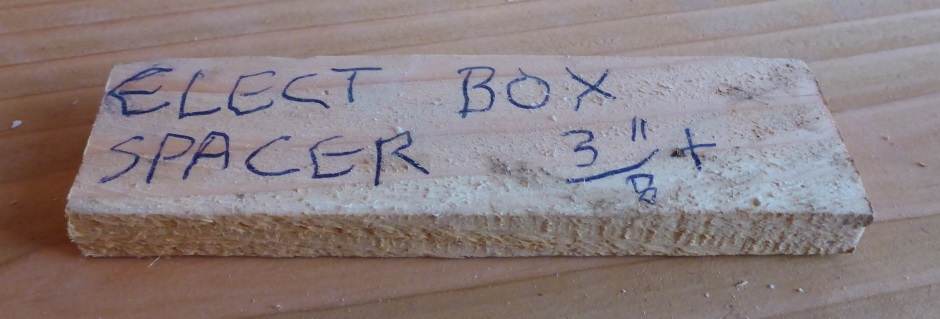

It is important to mount the electrical boxes accurately, both in height and in the amount they are set forward relative to what will be the back of the drywall. Assuming 3/8" thick wainscot facing wood then the electrical box should be 3/8" set forward. A spacer is used to set this distance consistently while screwing on the boxes.

Use a clamp too get the box positioned on the height line and with the right protrusion. Use a long extension on the screwdriver so the angle is not enough to cause the box to get pulled back by the screw tightening. Pre-drill holes in the side of the electrical boxes. Two screws are used on each side so the box is rigidly supported.

The electrical sockets are wired and screwed into the boxes before the wainscot facing wood is fitted.

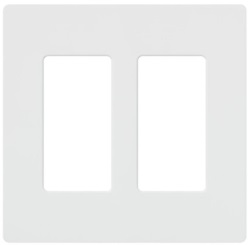

Electrical wall plates

In order to hide the larger than normal holes in the drywall necessary to clear the pre-installed electrical sockets it is necessary to use the biggest height wall plates you can get. The ones I use are from Lutron and they also look nice because they have no exposed screws. They have a base part that screws on to the spare holes in the electrical sockets and then the top part snaps on to hide the screws.

Purchasing details are

here .

Purchasing details are

here .

The electrical plates are used to hold on the drywall. Rather than using the screws that come with the Lutron wall plates, you need to use long screws, eg 1.5".

Details are

here .

Details are

here .

Internet Cat6

Cat-6 sockets are mounted using adapter plates that make them into Decora size inserts so that the same Lutron wall plates can be used. They are mounted such that the tabs on the Cat-6 cables are at the bottom.

Where necessary, put the Cat-6 in the top position, ie the secondary position. It is also ok to put it in the lower position when power outlets are not required at that location.

(Replace the following picture with one the right way up)

Flat screen wall mounting

The flat panel VESA mount can be attached directly to the concrete wall using a thin piece of wood glued to the concrete with a couple of bolts fitted. The VESA mount plate hooks over the bolt nuts.

Also provided is a power outlet that will be hidden behind the drywall.

Drywall with a hole just big enough to allow room for the VESA mount is attached.

Window sills

Inner sills below the window

Window sills are made from 2x12 lumber. The width is cut such that the sills at the side protrude past the drywall. The edge is rounded off using two 45 degree cuts. The cuts are 3/8" and are done on the table saw with the blade set at 45 degrees. Moving the table gate in by half an inch with the blade moved to 45 degrees will produce a 3/8" cut (because you lose 1/8" when the blade is moved to 45 degrees). They are cut to size and glued on using PL-Premium adhesive.

No screws are used because you don't want any screw heads visible.

Once the glue has fully dried the can be sanded and blended in with the sliding bucking wood.

Window upper sills

In addition to the 2x12 lumber glued on to make the inner window sills below the window, there are also sills of the same size and bevel glued on above the window. Temporary 2x4s cut to the appropriate length hold them in place while the glue dries.

Radiators

In order to readily meet Washington State Energy code without having to have lots of discussions about the house not needing much heating given all the insulation and thermal mass etc, I decided to use a bunch of electric radiators. To hide their ugliness, I mount them behind the drywall and provide wooden grills top and bottom.

Purchasing details are here

.

Purchasing details are here

.

Grab Bars

Info on the type I use is here .

Extractor Fan Countdown Timer

Info on the type I use is

here .

Info on the type I use is

here .

Ceilings

It is nice to show wooden beams. It lends detail to the overhead plane. It does mean that you can only run ducting east west, but that is ok with the appropriate planning.

Use 1'9" pieces of 3/4" oak flooring planks over the EPS between the beams. The planking is used to form 4' panels and then the panels are held in place using Velcro so you can get at the ducting. A safety strap is used to hold the panel when the Velcro is detached. Fire retardant varnish can be painted onto the wood planking.

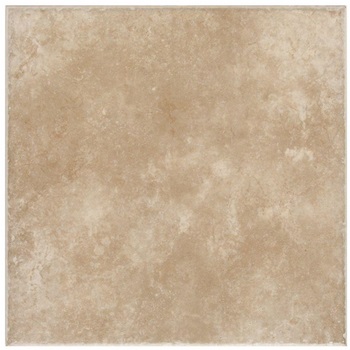

Large-format porcelain tile

Large-format porcelain tiles give the look and feel of natural stone at a much lower cost.

Fireplace

Some people think brick is going out of fashion. Using big timbers is potentially a better way.

TV Location

When considering living room design you want to think about the various "focus of interest". Typically they are three "focus of interest", ie the TV, the fireplace, and the view through the window. You want to have these separated by not more than 90 degrees (the maximum comfortable turning angle of your head).

You cannot make every seat in the living room the optimum seating position but you need to have at least two seats that are optimum. Other people in the room will have to put up with less than ideal seating.

Ideally the center of the TV screen should be at eye height when seated. That equates to the center being 42" off the floor. If the TV screen is 60" has a 2" high stand then the shelf it sits on should be about 2' high. In my case the shelf is the same height as the window sills (1' 7-1/2" from finished floor). Ideally I would use a wooden box pedestal with a height of 4.5". It is ok to make the shelf a little lower and this has the advantage that you can see over the TV to the window view behind when you stand up.

The ideal viewing distance is between 1.5 times and 2.5 times the diagonal screen width. For a 60" TV that means 7'6" - 12'6".

There is some logic for putting a TV above a fireplace because that combines two "focus of interests" in one place, but that means that the center of the TV will be way too high for optimal viewing.

Choosing a screen

If your living room is large then you want the biggest screen you can afford. This will allow more chairs in the room to have optimal viewing because they can be set further back so the arc distance is longer.

Personally I like a screen that has a very thin border bezel. As well as looking stylish, this means less of the window view behind is blocked.

Secondary screen

You may decide to have a primary viewing screen and a secondary screen. The main video entertainment will be on the main screen and the secondary screen will be used for displaying photos or news feeds or house control functions.

To allow for someone in the kitchen to not miss a vital part of the movie, it is sometimes useful to have a second screen that is also playing the main entertainment feed.

Window Blinds

When ordering blinds, specify the rough opening size, eg 36"x48". The manufacturer will deduct half an inch from the size you specify (which makes the blinds the same size as the actual window).

Curtains

In addition to the fact that heavy curtains look nice and can block out close to 100% of the light, using thermal curtains on windows is a big heat saver given that windows are a low R value compared with walls. With my thick walls, the space between the curtains and the glass is 1' 3-3/8" in the case of a 12" concrete wall and 11-3/8" in the case of an 8" concrete wall. Where necessary (eg to avoid the edge of the TV) the curtains can be draped into the space to reclaim some of the window sill area.

The curtains just come down to the top of the window sill (which is also the wainscot sill). Two ties to pilasters (at seating height and head height) are provided each side of the window to constrain the curtains when open to avoid constricting the view. Need a hook and eye on the wooden window bucking.

Automatic curtain opening/closing is problematical given the use of curtain ties.

A round steel pipe goes between the pilasters to form a curtain rail. Where there is a transition from 12" to 8" concrete, a joggle is bent into the pipe.

Electrical outlets in draws

In the kitchen and bathroom this allows appliances to be kept out of site and yet be quick to use. Also useful for charging phones etc.

Under-bed storage

Make a bed with draws underneith for socks, underpants, t-shirts, etc. Use high quality slides and sterillite boxes set into particleboard with 2x4 sides.

Tiling

Use 1" 40psi EPS over 6mil polyethylene.

Glue on the tiles to the EPS surface using foam adhesive.

I like brown rustic porcelain tiles...

Make the tile surface waterproof using epoxy grout. Need A & B epoxy parts and then add the color with part C.

https://smile.amazon.com/gp/product/B00FATZA8S/ref=ox_sc_act_title_5?smid=AGF3WDK3JPWO9&psc=1 $78.95 for 9 lbs

https://smile.amazon.com/gp/product/B002UPVMSC/ref=ox_sc_act_title_3?smid=AGF3WDK3JPWO9&psc=1 $22.76 coloring for 9 lbs

Match the grout color to the lightest color in the tile.

Cleanup is a little tricky so use...

Epoxy grout sponge...

https://smile.amazon.com/gp/product/B004ULVFBI/ref=ox_sc_act_title_2?smid=ATVPDKIKX0DER&psc=1

The slightly coarser epoxy grout sponges tend to remove excess epoxy grout from the tile surface much better.

Film remover...

https://smile.amazon.com/gp/product/B074MXG6RJ/ref=crt_ewc_img_dp_1?ie=UTF8&psc=1&smid=ATVPDKIKX0DER

Interior design

You need a neutral color background base and then add coordinated highlight color.

Shades of light brown or beige make for a good neutral background.

Neutral background

Three of the 4 walls in a room should be a neutral color. Something between off=white and beige.

The floor be a neutral color but can be a little darker brown than the walls. The ceiling should be neutral but can be a bit brighter, eg white.

Internal doors should be a neutral color, eg wood finish.

In a room have one of the 4 walls be a feature wall. Pick the wall that has the least openings as the feature wall. A highlight wall should have rich texture and/or richer color.

The other 3 walls should be neutral colors. If the feature wall is wood then its color should be darker than the neutral color walls.

Highlight color

Highlight color can be provided by...

Wall artwork

Floor rugs

Curtains

Candles

Chair cushion covers

Feature wall

House plants and flowers

Table lamps

LCD flat screens

Colored LED light strips

Wall art types...

Mondrian

Brightly colored flowers

Receding alleyways

Sunset skys

"Interior Designers" use scatter cushions, throw blankets, and false accessories to add highlight color but all these things in my opinion are not compatible with everyday living.

Use the same colors in the highlight items, eg the same colors in the wall artwork as in the rug.

Candles

Candles are another thing that can provide highlight color. Search or "candle making supplies". Add color and fragrance to soy wax. Could use lathe turned wood container. Could use low cost wine glasses eg $1.99 from Ikea.

Rugs

You can make a rug using a piece of carpet with a surround edge. The edge can be wood cut on a table saw to make an inset.

https://dengarden.com/interior-design/Seven-Principles-of-Interior-Design

Built-in shelves along one bedroom wall with a different Mondrian color on the wall in each shelf box.

Colored spotlights

Colored spotlights on the ceiling (or wall) to give touches of color.

Interior tree house

This is basically a mezzanine in a kids bedroom, but it is made to look like a small house on legs.

Could potentially hang it from the concrete ceiling, ie make it a ceiling pod, but using wood posts is probably more practical.

An indoor climbing frame (perhaps associated with the indoor tree house) is also good. Also a rope walkway (with wood planks).

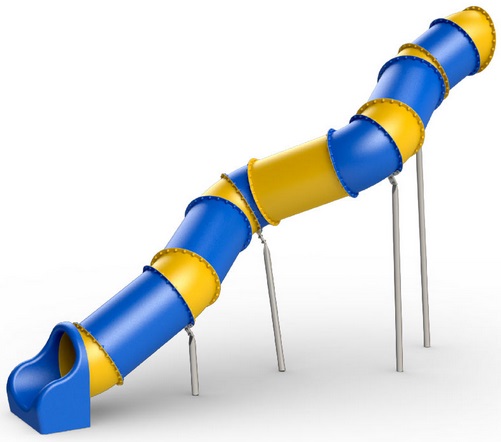

An indoor slide from the indoor tree house is definitely good.

Slide between floors

Need to cut a hole in the railings or wall and do a pipe slide to the floor below.

Slide outside diameter (with the bolt flange) is about 2' 10". The inside diameter is more like 2'6".

It will provide a splash of color (eg all yellow) in the vestibule. It starts on the bedroom landing and runs through the panty to come out between the kitchen and living room.

SwingSetMall Based in Bremerton WA

https://www.swingsetmall.com/custom-tube-slides/

https://www.swingsetmall.com/custom-tube-slide-information/#4

Detailed Play PRO, PO Box 638, Manahawkin, NJ 08050 Phone: 1-877-548-3100 Email: info@detailedplaypro.com

http://www.detailedplaypro.com/play-tube-tunnels.htm

https://www.ledonplay.com/tube-slides/

It's not impossible to build a wooden slide. It would be a square tube rather than a round tube. Line the bottom and sides with semi-rigid 8'x4' sheets of slippery plastic, eg PTFE.

Also do an outside slide off the main level deck.

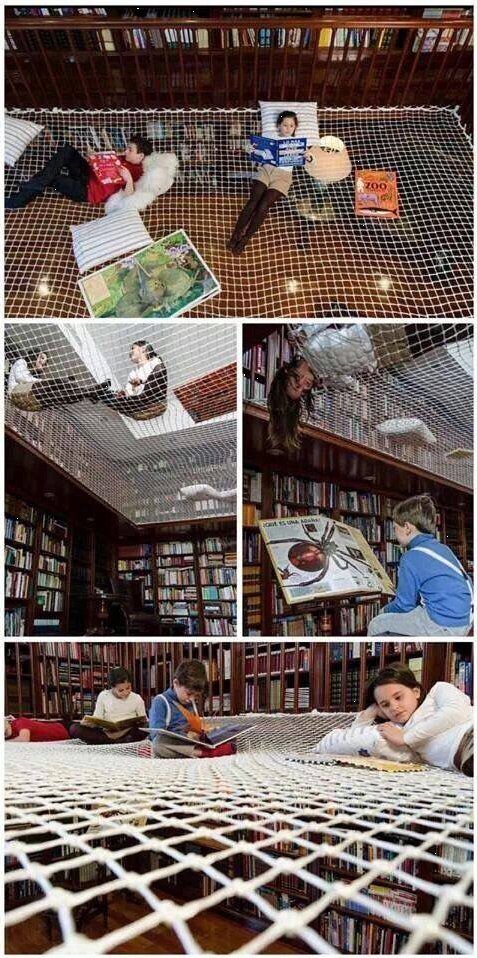

Net over floor opening

The net is a climbing net that can take the weight of adults. It allows light to come through (with a view upwards) and is also a great place to lay on to read a book.

Ceiling fans

As well as air movement, a ceiling fan is also an ornament and makes high ceilings look lower and the room more cozy.

Ceiling hung bed

Hang a bed from the concrete ceiling and make the height motorized. Need a strong base with guard railings round the outside. Use four HarborFreight winches mounted within the bed frame (just hooks in the ceiling). Getting them coordinated will be hard. Put lights in the bottom so it can be a light when in the fully up position.

Blind shelf supports

Put half inch steel threaded rod into the concrete wall tie holes. Drill 1/2" holes onto 1.5" thick shelf wood.