Rebar Chairs

The 3.25" ones I'm using are at http://www.amazon.com/gp/product/B000KKM260/ref=oh_aui_detailpage_o02_s00?ie=UTF8&psc=1 About $45 for 500.

For some cases the foundation design calls for 2.25" chairs...

http://smile.amazon.com/Prime-Source-Pneumatic-500pc2-1-Chair/dp/B00EKN1HLO/ref=pd_sim_sbs_60_2?ie=UTF8&dpID=31Y27S5bO%2BL&dpSrc=sims&preST=_AC_UL160_SR160%2C160_&refRID=0QHCCYGD8SFJA2A4DRFW $20.26 + $9.67 shipping for 500

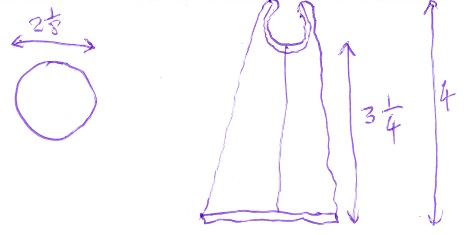

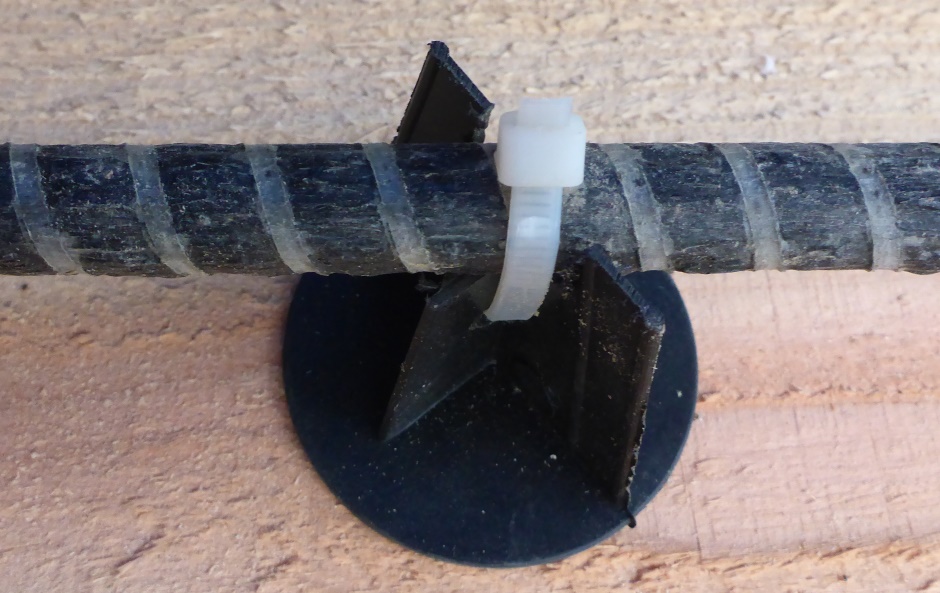

For some applications (eg over the slab area) they need to be modified with a bandsaw to get them to the right height. Here is a picture of a chair modified to support rebar (in this case half inch rebar) at a distance of 1.5" to the bottom of the rebar (1.75" to center of rebar).

First cut 2-1/4" chairs to a height of 2" using a fine blade bandsaw with a fence. Use a wood block jig to avoid having to measure each time. Then cut a 1/2" square notch in the top. Drill a 1/4" hole through the center at a diagonal.

Best chair material

I prefer to avoid steel in the concrete (to avoid rust and the possibility of spalling). Concrete chairs are good, but using plastic is less expensive (especially with shipping costs).

If you prefer you can use chairs made from concrete. Concrete chairs are nice because they are made of the same material (concrete) as what will be surrounding them, and thus have the same thermal expansion/contraction characteristics. That reduces the gap around the chair that water might try to get in. The downsides are the price and the shipping cost. My choice is to use plastic chairs.

You can even make your own concrete chairs using eg yogurt pots of the required size. If you make your own concrete chairs then you will need to embed galvanized wire so they can be attached to the rebar.

Rebar placement distances

For concrete poured on ground or uneven surface the ACI (American Concrete Institute) standard requirement is 75 mm (3") cover. The reason for a greater cover when pouring against ground is to ensure there is minimum adequate concrete cover of the rebar, which is the rebar's protection against corrosion. The ACI standard is normally adhered to and enforced in commercial construction, but is often ignored in residential construction although this part of the ACI applies equally to residential building.

ACI specifies:

Concrete cast against and permanently exposed to earth: 3“

Concrete exposed to earth or weather (up to and including #5): 1.5"

Concrete not exposed to weather or in contact with ground: 0.75"

In my case there are two reasons why the 3" rule does not apply. Firstly, the foundation concrete is not actually on ground but rather it is on multiple layers of polystyrene and waterproof membranes. Secondly, corrosion-proof rebar does not rust so does not need 3" of concrete protection.

The reason for using less than 3" is that rebar is for resisting tension and it will be more effective in a concrete beam if it is closer to the edge of the beam.

There is a strong argument for 0.75" being the required figure, but I typically use 1.5" as a minimum.