Home Site Map - Steps - Foundations -

Foundation Lining - Official Water Barrier

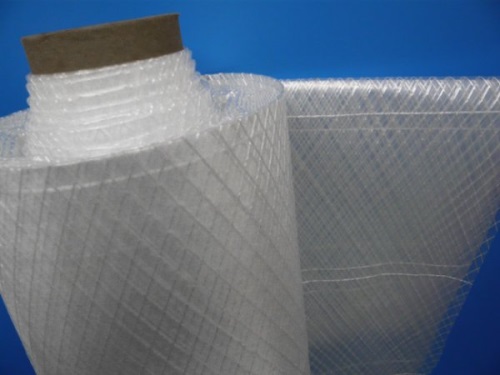

![]() Add the primary water barrier polyethylene sheet membrane.

Add the primary water barrier polyethylene sheet membrane.

Fit official water barrier

Clean out all debris

Use a wet/dry vac to clean the trenches and over slab area thoroughly.

Make absolutely certain there are no sharp bits of stone brought in on people's shoes.

Best to use a continuous sheet

It is very time consuming trying to do good joins between polyethylene sheets and the joins may decide to leak. It is far better to buy a custom made polyethylene sheet that is big enough to do the whole job without any joins. See here for purchasing details.

Install polyethylene sheet

Even though there may be some later refining of the fitting of the membrane, it is worth getting the positioning of the sheet approximately correct.

This in the official impervious water/air/vapor membrane that lines the entire underground area. It starts on the westward downhill side of the building with enough spare to go from 4-6 feet above grade, then down 2 feet to get to the Form-a-drain, then down the inside of the outer Form-a-drain, then along the bottom of the footing trench, then up the inner edge of the inner Form-a-drain, then across the first slab area, then down and up the inner wall footing, then across the middle slab area, then down and up the inner wall footing, then across the third slab area, then down and up the far footing, then up to 4 feet above grade. It is held in place using the wooden clamps on the outer upper form-a-drain.

Any excess will be used on the uphill side of the building. On the downhill side it is useful to mark with a marker pen 8' in from the sheet edge and align this with the top of the outer form-a-drain.

Don't forget to provide movement slack in case of slight subsidence. Put 2" extra flap in any place that the you think might experience movement. At minimum there must be about 2" of slack on the vertical outside of the footings.

Some creative folding and crumpling is needed at the corners. We are not looking for neatness in the folding of the sheet. The important thing is that it forms a continuous waterproof membrane. We do NOT want to cut the sheet to achieve neat folds. It's infinitely better to have crumpled up spare flaps rather than cutting to achieve neatness.

Seal openings for pipes (if needed)

If you have pipes through the slab (eg sewer or radon vent) then you need to cut openings to allow the pipes to come through. Cut a cross in the polyethylene sheet at the carefully figured out place, but keep the cutting to an absolute minimum as we are aiming for a sealed membrane. The flaps of the cut cross should face upwards around the pipe so they can be taped. Leave a bit of extra slack in the polyethylene sheet between pipes if there are adjacent pipes.

It is fundamental to have this sheet fully sealed so that no water gets through. Tape it well all around the perforations due to the pipes that come up through the slab. Use a couple of rings of double sided tape round the pipe and then single sided 2 inch tape on top, then single sided 4 inch tape on top of that.

Ensure no holes in polyethylene sheet

It is important that the polyethylene sheet has not been damaged. Thoroughly inspect it for holes. If any holes are found then repair them with single sided 4 inch tape.

Roll up spare polyethylene sheet

The spare round the edges can be laid over the sides of the upper outer Form-a-drain. It will be rolled up over the previous membrane sheet to prevent water getting between the sheets. The rolled up polyethylene sheet should be arranged so that it does not go further than 3 feet beyond the top of the form-a-drain.

There are now two pieces of 6 mil polyethylene sheet coming up round the outside of the footing trenches. To avoid letting water get between the sheets, make sure the official polyethylene membrane completely covers the more tightly rolled up first polyethylene termite/radon membrane.