Concrete

What is concrete?

Concrete is primarily a mixture of Portland cement, aggregates (sand and gravel, and water. The Portland cement is the glue that holds everything together. The large aggregate is typically pea gravel or crushed rock or larger round rock. Typically the large aggregate is between 3/8" - 1" in size. The sand fills in the gaps between the large aggregate. Concrete also typically has various "Admixtures" / "Admixes" to give it the right characteristics for different applications.

You can buy bags of dry concrete mix from your local home center that you just add water to, but if you need a lot of concrete then it's best to buy it ready-mixed by the concrete mixer truck load. The concrete supplier will be able to supply a mix to your requirements and it comes in a truck ready to pour.

Dry concrete mix has silica dust in it (which is harmful to your lungs) so it is not good to do too much mixing of concrete yourself. Ready mixed concrete does not have dust so is much safer. If you do any mixing of concrete yourself then wear a mask.

Concrete continues to gain strength after it is initially set thanks to a chemical curing process. It is not actually a drying process and in fact it is best for concrete to "dry" underwater as that reduces cracking. The compressive strength of concrete depends on the proportions of Portland cement, sand, gravel, and water in the mix. It is expressed in pounds per square inch (psi) after it has cured for 28 days. Building code requires at least 2500 psi (after 28 days) for regular house foundations and 3000 psi (after 28 days) for garage floor slabs and seismic areas. For the foundation on a concrete house (which is very heavy) and the concrete walls you should consider 3500 psi as the minimum, but preferably go higher eg 4000 psi.

HUD says concrete must meet ASTM C 94. This spec sets sensible default characteristics for concrete where a specific spec item from the customer has not been specified.

Use as little water in the mix as possible. The less the water, the better the concrete. Certainly a water to concrete ratio of less than 0.55, but really it should be in the 0.45 - 0.5 range.

For maximum strength you want to have as much Portland cement in the mix as possible. I use 6 bags of Portland cement per cubic yard which gives a concrete with a strength in excess of 4000 psi.

Concrete shrinks as it dries. It shrinks 1/16" for every 10 feet of length.

Ordering

A concrete truck holds about 10 yards (ie cubic yards) of concrete.

Some concrete suppliers may be prepared to sell a part load of concrete rather than only full truck loads, but the costs associated with this vary by supplier, so you need to ask and negotiate. If you are only ordering a part load then it could cost you a $30 fine for every yard that you don't want in the truck. If you are ordering more than one truck load then they will probably wave the part load fee on the last truck.

The price of concrete is a bit variable volatile but can be down to about $100 per yard, ie about $1K per truck load. A more typical large quantity price is $110 per cuyd.

Measuring the length times the width, then multiplying it by the depth, in feet or a decimal fraction thereof will give the total cubic feet of material required. To convert this number to cubic yards, divide it by 27. The rebar will reduce the amount of concrete slightly but not by much, as will window openings.

You need to coordinate with both the dispatch person at the concrete company and the person at the boom pump supplier to make sure they are both on site at the same time. Typically the concrete supplier will give you a job order number that you tell the pump truck company, although really it is up to you to make sure everything is properly choreographed.

Keep the concrete dispatch person's number handy on your cell phone so you can check on the exact delivery time and can chase up if necessary. Throughout the day, keep in close contact with the dispatch person.

You will typically have one hour per truck to unload the concrete truck. You want the next truck to arrive well less than an hour after the previous truck to avoid a cold joint.

It is worth posting someone at the end of your road so that they can flag down the driver and guide him to the site. If the driver gets lost then your whole schedule will be thrown off.

General info on Admixtures and concrete characteristics

You will want to work with your concrete supplier to arrive at the perfect mix for your application, but here is some general info on admixtures and other concrete characteristics.

Concrete type

The Portland cement comes in different "Types". Type 1 (General purpose) is typical for residential applications. Type II produces less heat. Type III (High Early) is used when you want it to set quickly. Type IV produces even less heat. Type V (Very sulphate resistant) is used if the soil or groundwater in contact with it is very alkaline.

Many concrete suppliers use Type I-II cement which is a good choice, ie it is general purpose without too much heat.

Aggregate

In practice the aggregate is likely to be mainly determined from what is most common in your area.

Using 3/4" is ok in an 8"

concrete wall.

Using 3/4" crushed rock is marginally stronger than pea gravel

because the rocks interlock.

Smaller aggregate allows the

concrete to flow better.

HUD says aggregate size shall not be larger than 3/4".

Some suppliers use round river rock as the large aggregate. If you are using round rocks then it is probably ok to go up to 1" rock size as round rock flows better than crushed rock.

In my case I use 3/8" pea gravel as this is what I was able to get the best price on. I like 3/8"pea gravel because it flows well and gets into all the nooks and crannies.

PSI

Building code: For the slab it must be minimum of 3000 PSI because the floor slab is also a garage. Also HUD says minimum of 3000 psi in seismic D1.

To provide greater strength to stand up to earth quakes, it is better to use a higher PSI in the walls, eg 4000 - 5000 psi.

The rule of thumb is that for every 94lb sack of Portland cement that you add to a yard of concrete you get an extra 1000 psi. Each bag of Portland cement costs less than $10.

The quoted psi figures are after 28 days of curing time.

A good baseline figure to specify is 4000 psi.

Slump

This specifies the flowability (plasticity) of the wet concrete. A vertical cone shaped mold is filled with concrete and the amount the concrete slumps down (in inches) is measured. A higher figure means it flows more. A slump test is typically used to make sure the concrete is not too wet, but water is not the only factor.

People think that slump is just a measure of how much water is in the concrete. Certainly adding more water will increase the slump, but adding water will reduce the strength of the concrete. However, the slump can also be made greater by adding a plasticizer (aka High Range Water Reducer), which will not hurt the strength.

The concrete needs to be flowable. For ICF it is typically recommended that the slump is not more than 6" slump as this creates excessive pressure on the ICF blocks that might cause a blow out. HUD says not more than 6" slump for ICF. Personally I like a 4" slump from a water perspective that is brought to an 8" slump by adding plasticizing (HRWR) admixture. Check the slump just before the pour. Look into the mixer to see how the concrete flows over the mixing blades. It should flow over the blades.

Water content

Adding water is a common way to increase the slump and make the concrete more flowable, but water will also reduce the strength of the concrete. One gallon of water added to a cubic yard of concrete reduces the strength by about 200 psi. Don't let the concrete mixer truck driver add water (they have water stored in the truck).

To get concrete to properly set you only need a water/cement ratio of about 0.25. Adding water beyond that is just to improve the flowability. The water/cement ratio should be no more than 0.45 - 0.5.

Air content

Air entraining agents are liquid chemicals added during mixing to produce microscopic air bubbles in the concrete. The bubbles improve the concrete’s durability and increase its resistance to damage from freezing, thawing, and de-icing salts. Air entraining admixtures improve workability and help reduce bleeding and segregation. It also acts as a plasticizer so makes the concrete flow better with less water. The bubbles contribute to workability by acting as a sort of lubricant for all the aggregates and large particles in a concrete mix. For exterior flatwork (parking lots, driveways, sidewalks, pool decks, patios) that is subject to freezing and thawing weather cycles, or in areas where deicer salts are used, specify an air content of 5 to 7%. Air-entrainment is not really necessary for interior structural concrete since it is not subject to freezing and thawing, but as mentioned it does increase flowability. In high cement content concretes adding air will reduce strength by about 5% for each 1% of air added, (but in low cement content concretes adding air has less effect).

Using air entrainment is not compatible with using a water proofing agent (such as Xypex). You need to choose to use Xypex OR choose to use Air Entrainment. In my case I have a polyethylene membrane to keep the concrete dry, so I can do without the waterproofing admixture. I can also do without the air entrainment because all of my concrete is insulated (with polystyrene) so there is no danger of freezing (and anyway there will not be any water to freeze).

Water reducers

Used for two different purposes:

Lower the

water content and increase the strength.

Obtain higher slump (ie greater flowability) using the same water

con

Regular water-reducers will generally reduce the required water content for a given slump, up to about 10%. This increases strength. Water-reducers are used to increase slump for pumping concrete and are used in hot weather to offset the increased water demand. Water-reducers can potentially give slump loss problems, ie you get a high slump immediately after it's added but not long after the slump reduces and the concrete stops being as flowable. Water-reducers tend to retard concrete (which I like). Regular water-reducers are termed Type A Chemical Admixtures in ASTM C 494.2.

Many important characteristics of concrete are influenced by the ratio (by weight) of water to cementious materials (w/cm, otherwise known as water/cement ratio) used in the mixture. By reducing the amount of water, the cement paste will have higher density, which results in higher paste quality. An increase in paste quality will yield higher compressive and flexural strength, lower permeability, better resistance to weathering, improve the bond of concrete and reinforcement, reduce the volume change from drying and wetting, and reduce shrinkage cracking tendencies.

Make sure the water reducer used is Organic (Inorganic typically means lead (Pb) which is bad).

If you want to go further than a regular water reducer then instead use an HRWR as described below (and that is what I recommend).

High Range Water-Reducers (HRWR) (Plasticizer)

High range water reducers (aka plasticizers) make concrete more plastic and workable with less water (ie without reducing strength).

A special class of water reducers are often called super-plasticizers. HRWR’s reduce the water content of a given concrete mix from 12 to 30%, which increases strength. HRWR’s can also greatly increase the slump to produce “flowing” concrete. For example, adding HRWR to a concrete with a slump of 3 to 4 inches can produce a concrete with a slump of about 7-9 inches. Within an hour or so the concrete will return to its original slump. HRWR’s are covered by ASTM Specification C 494.2 Types F and G, and C 10175 Types 1 and 2.

A plasticizer (HRWR), ie a high slump) will increase the pressure on your concrete formwork, so make sure everything is well braced. Having concrete that flows well is however necessary to avoid air voids in concrete walls and even in foundations with lots of rebar.

Make sure the HRWR used is Organic (Inorganic typically means lead (Pb) which is bad).

Type F is a good choice (but Type G is even better as it will give some added retardation).

Type F Superplasticizers should ideally be dispensed on to the batch immediately before discharge for placement. This is because HRWRs suffer from rapid sump loss, ie cannot maintain the high slump for very long. The slump loss problem can be overcome by adding the admixture to the concrete just before the concrete is placed, however there are disadvantages to such a procedure. The dosage control, for example, might not be adequate, and it requires ancillary equipment such as truck-mounted admixture tanks and dispensers. Adding admixtures at the batch plant, besides dosage control improvement, reduces wear on truck mixers and reduces the tendency to add water onsite. New admixtures now being marketed can be added at the batch plant and can hold the slump above 8 inches for more than 2 hours.

The best modern HRWR are polycarboxylate based. BASF Glenium is a good choice. Use Type A/F BASF Glenium 7500. Supposedly it takes 5-7 ounces per extra inch of slump required. To go from a 4" slump to a 8" slump needs 20 - 28 ounces of Glenium per yard of concrete. Glenium costs about 32 cents per ounce, ie is not very expensive for for the benefit it provides. In practice I have found that in my high cement mix you need more than 20 ounces per yard. I recommend 28 ounces. If you are using more than this then you should also use an organic viscosity modified admix (VMA)

Viscosity Modified Admix (VMA)

A VMA (Viscosity Modified Admix) helps to stop concrete with a high slump from separating. Separating refers to the stone in the mix falling to the bottom while the fine cementious part staying at the top. What you want is for the two to stay together. You want to keep the viscosity fairly high even when you have high flowability.

It doesn't need much VMA because even with lots of HRWR (Glenium) the slump will still probably be below the segregation point. Having the VMA is however a useful safety measure to ensure segregation is not a danger.

You want to use an organic VMA.

The best choice of organic viscosity modified admix is BASF Rheomac VMA 450.

Retarders (Inhibitors) (Hydration Stabilizer)

Chemicals which delay the initial set of concrete by an hour or more. Retarders are often used in hot weather to counter the rapid setting caused by high temperatures. For large jobs, or in hot weather, specify concrete with retarder to allow more time for placing and finishing. Most retarders also act as water reducers. Retarders are covered by ASTM C 494.2 Types B and D. Retarders also reduce initial stress cracking.

For inexperienced concrete workers, you want as much retarder as possible to give more time to work the concrete surface smooth.

Use an organic retarding admixture.

A retarder will help avoid cold joints between concrete lifts/pours.

It will not help extend the slump loss time associated with HRWR. It is better to pick a HRWR that can maintain the higher slump for a longer period. The concrete will still be workable even after the temporarily elevated slump has gone away.

The term "Hydration Stabilizer" is typically used to apply to the most high tech retarders. They typically provide very good control of the concrete setting process. Using a "Hydration Stabilizer" is the best choice. Typically specify 2 hours of extended workability (or ideally even greater time).

A good choice for a retarder is BASF MasterSet Delvo. The maximum amount to use is about 5 ounces per 100 wt of Portland cement. This equates to 34 ounces per yard if you are using 6 sacks of Portland cement per yard. Delvo does not contain any known hazardous substances. It costs about 30 cents per ounce so it increases the cost of a yard of concrete by about $10.20, ie about $100 per truck load. I regard this as a little expensive.

Having a retarder is useful on the last truck load(s) on the foundations as it allows the slab to be worked nice and flat. On concrete walls it is better to do without the retarder because you want the concrete in the bottom of the wall to set slightly as you go up the wall in order to reduce the possibility of blowouts.

Accelerators

Reduce the initial set time of concrete. Liquid accelerators are added to the concrete at the plant. Accelerators are used in cold weather to get high-early strength. Accelerators do not act as antifreeze. Instead they speed up the strength gain and make the concrete stronger to resist damage from freezing. Accelerators are sometimes used to allow finishing operations to begin early. Calcium chloride is the most commonly used accelerator, although non-chloride (non-corrosive) accelerators are available. Calcium chloride is specified at not more than 2% by the weight of the cement. Pre-stressed concrete and concrete with embedded aluminum or galvanized metal should not contain any calcium chloride because of the potential for corrosion. See NRMCA Publication No. 173.3. Accelerators are covered by ASTM C 494.2 Types C and E.

I do not want any accelerator. For me, slow setting is good and I don't want the corrosion that an accelerator can cause. Accelerators are only used by contractors on a tight schedule.

Polypropylene fibers

Novomesh 950 from "SI Concrete Systems" (Chattanooga, Tenn.) is a mixture of polypropylene tooth picks and tufted polypropylene. Some people call it Fibermesh, but Fibermesh is just the polypropylene toothpick part. Novamesh 950 reduces surface cracking and potentially reduces the amount of rebar required (or putting it another way, it increases the strength).

It will reduce the flowability of the concrete so it is best to not use too much.

For situations where you want it, use Novomesh 950 with half of a 5lb bag per cubic yard. It costs about $25 per 5lb bag, ie $12.50 per cubic yard.

The concrete supplier (eg in my area Cadman or Calportland) will supply the Novomesh 950, but the direct rep in my area is:

Mike Schroeder

Territory Manager

4035 120th Avenue S.E.,

Bellevue, WA 98006

Phone: 206-218-3156

Fax: 423-553-3041

Email:

mike.schroeder@propexus.com

The cost is significant and it has the flowability negative so it is best not to use it on the lower pours in the foundation. You should use it on the last foundation pour. ie the slab (to avoid slab cracking) and the last pour for the concrete floors. Because of the flowability negative I decided not to use it on the concrete wall pours.

My local concrete supplier (Cadman) has now introduced alternative polypropylene fibers that they call "stealth fibers". The main advantage being that it is less expensive than Novomesh. It is $7 per cuyd. This is what I chose for the 60 cuyds needed for my slab. The Cadman fibers are actually Basf M100. https://www.master-builders-solutions.basf.us/en-us/products/masterfiber/1659

If you need to buy polypropylene fibers yourself then you can use

Basf M70

(even though the tensile strength is less than M100).

https://smile.amazon.com/gp/product/B01N7S6HGS/ref=ox_sc_act_title_1?smid=A2H66OENE752WR&psc=1

1.5 pounds $10 + $5.49 ship

Waterproofing admixture

An additive that seals the micro cracks that form in setting concrete. It makes the concrete waterproof and helps avoids corrosion. In North America the best product is Xypex. The only problem is that it is very expensive.

Xypex is added to the concrete mix at the time of batching. The mix consists of Portland cement, very fine treated silica sand, and various active proprietary chemicals. These active chemicals react with the moisture in fresh concrete and with the by-products of cement hydration to cause a catalytic reaction which generates a non-soluble crystalline formation throughout the pores and capillary tracts of the concrete. The concrete becomes permanently sealed against the penetration of water or liquids. The concrete is also protected from deterioration in harsh environmental conditions.

Xypex Admix C-1000 is designed for typical Portland cement-rich concrete. Xypex Admix C-2000 is designed for projects where extended retardation is required. If using Xypex C-2000 it may be ok to do without a separate retarder admixture.

Xypex Chemical Corporation

13731 Mayfield Place

Richmond, BC, CAN V6V 2G9

Web Site: www.xypex.com

E-mail: info@xypex.com

A concrete supplier (such as in my area Cadman or CalPortland) can supply Xypex (or equivalent from a different manufacturer) as part of the mix. It is worth checking that they have the instructions on how it should be mixed in at the concrete plant.

Concrete with a water/cement ratio of less than 0.5 will be fairly waterproof even without using a waterproof admixture.

Waterproofing admixtures are very expensive so it is hard to justify their use. Your money is better spent (and also a lot less money) by adding more Portland cement to the mix and by having a 6mill polyethylene sheet waterproof membrane.

Using air entrainment is not compatible with using a water proofing agent (such as Xypex). You need to choose to use Xypex or choose to use Air Entrainment. In my case I have a polyethylene membrane to keep the concrete dry so I can do without the waterproofing admixture.

Self-compacting admixture

Makes the concrete flow better into all the nooks and crannies. The only slight worry is that if the lift height in a concrete wall is too great, there would be an increased possibility of a blow out, but good wall bracing can avoid the problem.

Having a high slump due to a HRWR (High Range Water Reducer) does make concrete fairly self compacting so separate self-compacting admixture is probably not required.

The local concrete supplier in my area (Cadman) has a product called PerformX which is a type of Self Compacting Concrete (SCC). I believe it is just lots of HRWR with lots of VMA to stop it separating.

Shrinkage reducing admixture (SRA)

Portland cement shrinks as it loses moisture from its extremely small pores. As the moisture is lost in these small pores, the surface tension of the remaining water tends to pull the pores together which results in a loss of volume over time. This can be overcome using a shrinkage reducing admixture (such as Eclipse 4500). Shrinkage reducing admixtures (SRAs) are designed to decrease the effects of drying shrinkage by reducing the surface tension in the pores.

Having an SRA is a benefit, but is in practice not really required.

Crack-reducing admixture

This reduces cracking during the drying process.

The best bet is BASF MasterLife CRA 007.

Personally I prefer a crack reducing strategy of using polypropylene fibers and curing the concrete under water.

PH value

Concrete is by its very nature very alkaline, something like a PH of 12 or 13. Fiberglass rebar is rumored to not like a PH value above about 13. In practice the concrete supplier is unlikely to be able to adjust the PH so it will come out between 12 and 13.

Corrosion inhibitor

Corrosion inhibitor admixtures are very expensive and they are not organic. It is best to avoid specifying them, particularly as I am not using steel rebar so there is no need.

Fly-ash and/or slag

This is a by-product from coal power stations. Some people think it makes concrete "greener". I have some significant health concerns about using it so for me I rate it as a definite NO. I also want lots of Portland cement because Portland cement is the glue that holds everything together and substituting flyash will reducing the amount of gluing.

My mix specs

Footing mix

6 Sacks of Type I-II Portland cement per yard

3/8" Gravel

Greater than

4000 psi at 28 days

4" slump (delivered as 8" because of the HRWR)

Absolutely No flyash or slag

Maximum w/c ratio: 0.48

HRWR (plasticizer) - 28 ounces BASF Glenium 7500 per yard

No VMA

No crack-resistant admix

No fibers

No Retarder

No accelerator

No air entrainment

No waterproofing

Slab mix

6 Sacks of Type I-II Portland cement per yard

3/8" Gravel

Greater than

4000 psi at 28 days

4" slump (delivered as 8" because of the HRWR)

Absolutely No flyash or slag

Maximum w/c ratio: 0.48

HRWR (plasticizer) - 28 ounces BASF Glenium 7500 per yard

Cadman stealth fibers

No VMA

No Crack-resistant admix

No Retarder

No accelerator

No air entrainment

No waterproofing

Wall mix

6 Sacks of Type I-II Portland cement per yard

3/8" Gravel

Greater than

4000 psi at 28 days

4" slump (delivered as 8" because of the HRWR)

Absolutely No flyash or slag

Maximum w/c ratio: 0.48

HRWR (plasticizer) - 28 ounces BASF Glenium 7500 per yard

No VMA

No fibers

No retarder

No accelerator

No air entrainment

No waterproofing

Floor mix

6 Sacks of Type I-II Portland cement per yard

3/8" Gravel

Greater than

4000 psi at 28 days

4" slump (delivered as 8" because of the HRWR)

Absolutely No flyash or slag

Maximum w/c ratio: 0.48

HRWR (plasticizer) - 28 ounces BASF Glenium 7500 per yard

Cadman stealth fibers

No VMA

No Retarder

No accelerator

No air entrainment

No waterproofing

Concrete suppliers

Rather than just talking with one concrete supplier, you need to find the 2 or 3 suppliers in you local area in order to get the best mix and the best price. Hopefully the presence of competition will reduce the price.

Cadman

Jamey Ingersoll - Sales

jingersoll@cadman.com

425-766-7234

Larry Busch - Sales Manager

larry.busch@cadman.com

(425) 961-7153

Cindy Jackman - Dispatch and ordering

cjackman@cadman.com

Stacy Fenton - Store Manager

sfenton@cadman.com

425 961 7291 (Stacy direct)

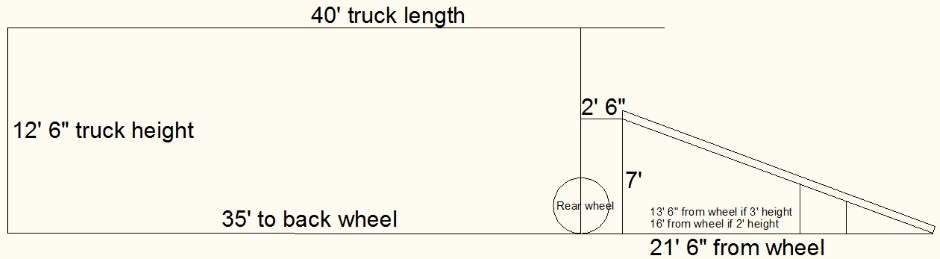

Concrete truck chute distance

In most cases it is best to use a pump truck, but if you do decide to use the concrete truck chute, here are the important measurements.

The truck width is 9'6".

Adding plasticizer on site

If the concrete is transported from the mix plant with lots of plasticizer there are a couple of issues to be aware of. Firstly the plasticizer has a diminished effect over the 45 minutes it takes the truck to get to your site. Secondly if there is a steep uphill part of the route then concrete with an 8" slump may slop out of the back of the truck and create a mess on the road.

I managed to persuade my concrete supplier (Cadman) to only add half the plasticizer at the mix plant to make the slump 6" with the rest added on site to get it to an 8" slump. Concrete suppliers strongly prefer to add everything at the mix plant because they have more control. If adding on site, you need to wait at least 5 minutes after adding the extra plasticizer before emptying it into the pump truck.

Don't add water

Never let the concrete truck driver to add water. Any watering should just be to lightly spray the shoot to get the concrete to start flowing down the shoot.

Screeding

It is good to do the screeding as you go rather than adding all the concrete and then screeding. The reason is that you never want to have too much concrete so that you have to shovel it out. Screeding as you go gives you somewhere to drag any excess concrete to and lets you better judge the amount of concrete needed to finish the job.

Curing concrete

For proper curing it is necessary to control the rate of evaporation of the water from the concrete (and avoid water temperature extremes such as freezing). This is particularly important in the first week.

Try to keep sun off it as that will cause more evaporation of water.

Keep it consistently wet - not dry wet cycles. Keeping a slab completely submerged in water by forming a pond on top is the best technique. Covering in a polyethylene sheet is also reasonable. Can also use a garden sprinkler.

A temperature (outside) of about 50 degrees F is ideal. Not below 40 degrees F. Ideally not above 60 degrees F, but up to 79 degrees is ok.

Underwater curing measures for a slab should begin when concrete is no longer susceptible to damage and the surface begins to dry (ie as accumulated bleed water evaporates faster than water rising to the surface) and certainly no later than half an hour after the sheen caused by the water has gone. In practice this will be about an hour after the finishing has been done on the slab and you can walk on it in flat bottomed shoes without leaving foot prints.

To create a pond, pull up the waterproof membrane round the outside of the slab and make sure it is supported to a height of at least 2 inches. At absolute minimum you need a water height of 1 inch. Ahead of the concrete pour it is a good idea to ensure the membrane can easily be pulled up and to figure out how you will be able to support it. Strips of 2" EPS is one way to support it.

Fill the pond with clean water from a hosepipe. Keep the pond on top of the concrete for at least 3 weeks.