Home Site Map - Steps - Roof and Attic -

Metal roofing

Details on metal roofing can be found here .

Slate roofing

Rather than using metal roofing, my roof uses slate. The great things about slate is that it is not degraded by UV and it will not rust or degrade in any other way.

The biggest issue is getting permission from the building inspector to be allowed to use slate. Slate is heavier than other roofing solutions so the issue in earthquake zones is having that amount of weight that high up in the building given the lateral forces in a quake. Your structural engineer needs to check that the walls will be able to withstand the lateral quake forces.

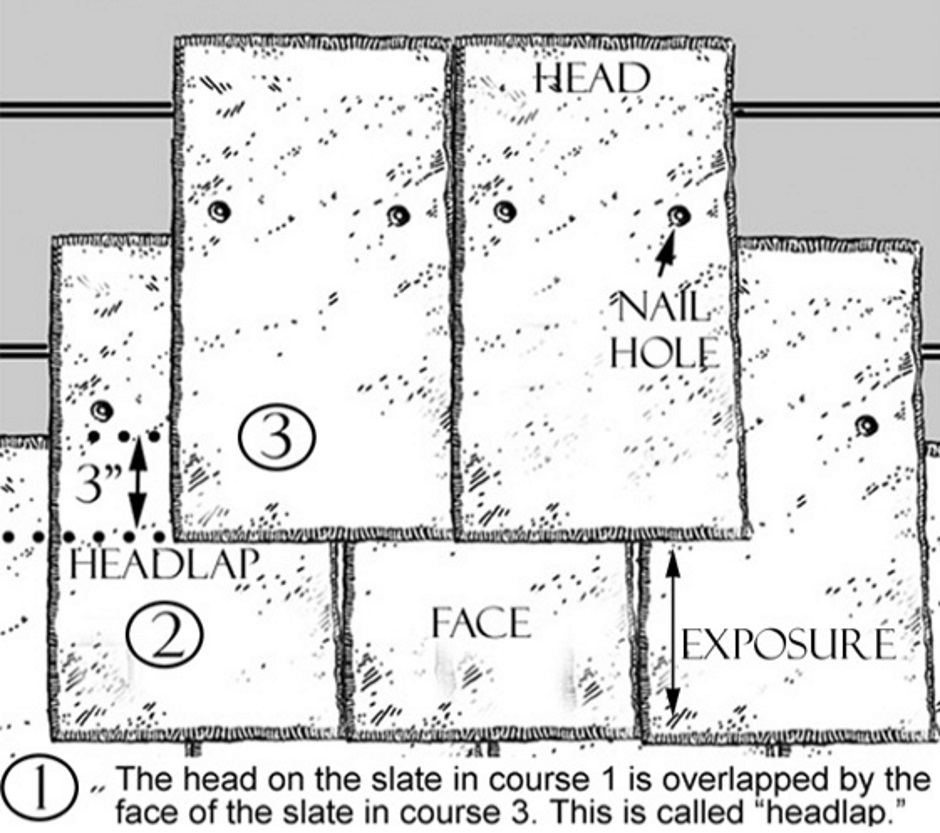

Here is a picture of how slate roofs are typically done...

In my case there is 12" of EPS over the roof decking so it is not possible to have wooden batons. What I do have is modern adhesive (PL-Premium) that can stick the slate tiles together, and Foam Adhesive that can glue the tiles to the EPS.

Even though the combination of the foam and PL-Premium adhesive will do a very good job of permanently securing the tiles, you still want it to be impossible for any tiles to fall off the roof and hurt someone. A stainless steel safety wire is used to thread through two holes in the top edge of each tile to catch any tile that somehow becomes loose. The wire goes horizontally along each row of tiles and attaches at the east and west roof edges. It is horizontal because the roof is implemented in horizontal rows, working from the bottom to the top.

Malin - MS20995C Stainless Steel Safety Wire \ Lockwire, Canister, 0.051 Dia, 143 ft.

https://smile.amazon.com/gp/product/B00945V5QU/ref=ppx_yo_dt_b_asin_title_o00__o00_s00?ie=UTF8&psc=1 $16

Also through the two holes put stainless steel large head nails (eg 1.75") into the EPS to hold the tiles while the glue is drying.

Simpson Strong Tie S510ARN5 5D Roofing Tile and Slating Nails 1-3/4-Inch and 10-Gauge, Ring Shank 304 Stainless Steel, 5-Pound, 630-Piece

Common tiles are 400mm x 250mm, ie 15-3/4" x 9-7/8" (Called 16x10). They are available with a thickness of 6mm (5-7), 7mm (6-8), or 8mm (7-9). Using 6mm has the advantage of reduced weight (which is important in earthquake areas). It is possible to get 600x300 tiles (6-8mm thick). Choosing larger tiles reduces the installation time and decreases the number of nails and amount of stainless wire. It is worth asking what are the largest tiles that can be supplied with commodity pricing.

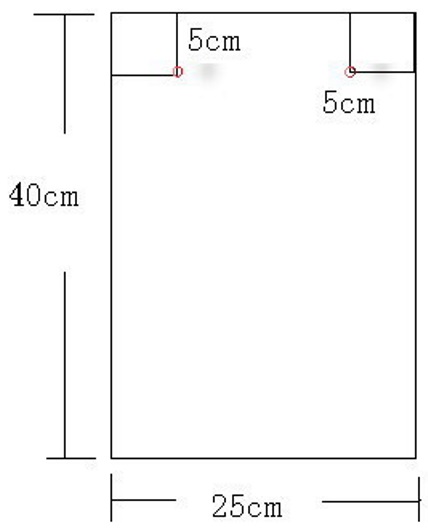

Roof tiles typically come with two holes. Here's an example diagram from one supplier.

Relative to the above drawing, the holes should actually be 1.25" to 1.5" from the outer edge. This makes a better distance between the nails which makes them further from the slit between the tiles above where the water comes in.

Check that your slate tile supplier gives holes that are countersunk (which is typically done by punching the holes rather than drilling them).

For 16x10 tiles, the distance between rows is about 6.5" to ensure the holes are covered in the next but one layer.

10x16 tiles need a headlap of 3" and an exposure of 6.5”. Start with the height of the slate (16") and deduct the headlap, then halve it to give the exposure. The exposure is also the pitch of the horizontal lines you will draw up the roof.

At the eves it is not a bad idea to increase the headlap to more than 3" to help combat ice dams. http://slateroofers.org/downloads/SRCA_Architectural_Standards_V1.pdf

Shipping and price

The tiles come from China in a 20' container. A full container can hold about 1000 sq meters. 1000 square meters, it is around 19 Metric tons. For 400x250mm slates, 1000 square meters will be 10,000pcs. One crate will pack 540 pcs, so 1000 square meters will be 18-19 Crates.

10,000 tiles (1000 sq m) will cover a roof area of 444 square meters

(4,779 square feet).

One roof side (ignoring porticos) is 14' x 66' =

924 sq ft

Very approximately, with the 2 sides, porticos, and cupola,

say 3,250 square feet. Extras used for guest house and other

buildings to achieve a consistent look across the property.

Each tile costs about $0.892 , so 10,000 tiles cost $8,920 + $2,500 shipping.

Installing

Want a 1.5" drip edge on the bottom edge and 1" on the gable ends at the sides.

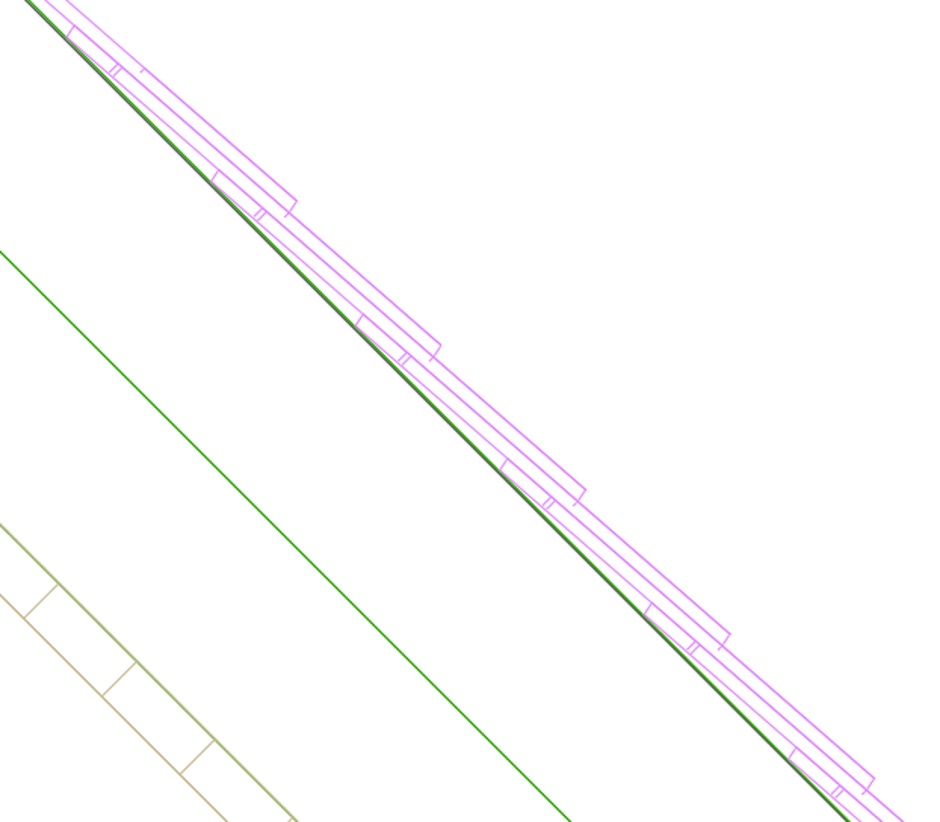

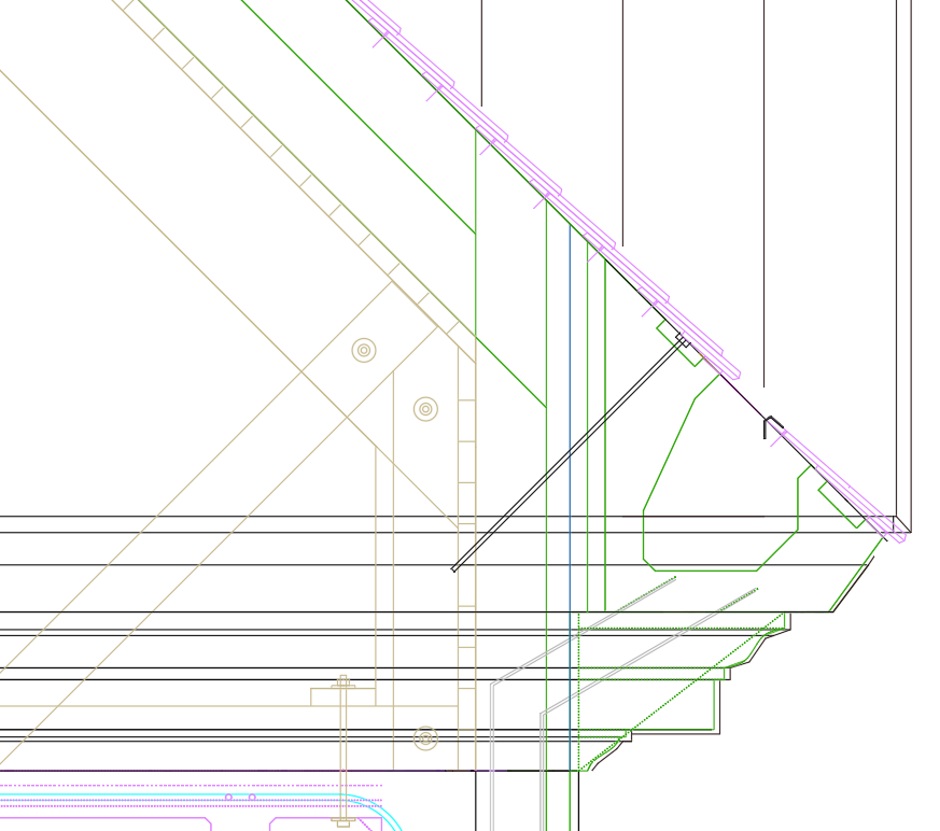

Do an AutoCAD drawing to show the overlaps and fit within the available roof height.

At the bottom edge you start with a Cant strip to give the horizontal base row the same slope as the rest of the tiles. You can glue on a 1" wide cut strip of tile.

The starter course at the bottom edge are upside-down slates laid horizontally.

Headlap should be 3". Headlap is the overlap each slate had over the slates two courses below.

Slates should be cut on the back side.

Draw lines to show where the top of the slates go.

A counter-sunk nail hole is important so the head does not rub on the tile above. That's why people tend to punch the holes rather than drill them. Can be drilled and counter-sunk.

When supplied on pallets, slates are not to be used from one pallet at a time, but are to be used from all pallets simultaneously in order to blend the various pallets uniformly on the roof.

Do not walk on a slate roof!

Info

http://www.traditionalroofing.com/TR8_installation.html